Premium Metal Carved Panels & Cleanroom Panels: Customizable Core Materials for Industrial & Construction Needs

Meta Description: Explore our factory-made metal carved panels (383mm width, PU/foam/rock wool cores) and cleanroom panels (1150mm width, foam/rock wool options). Durable, fire-resistant solutions for construction & purification projects.

In the fast-evolving construction and industrial purification sectors, the demand for high-performance, dimensionally stable building panels is soaring. As a professional manufacturer specializing in metal carved panels and cleanroom panels, we are committed to delivering tailored, quality products that meet diverse project requirements. Our metal carved panels feature a fixed width of 383mm with three core material options, while our cleanroom panels come in a standard 1150mm width with conventional foam and rock wool cores—ideal for industrial workshops, cleanroom facilities, exterior wall cladding, and more. This article dives into the specifications, core material advantages, and application scenarios of our panels, helping you select the perfect solution for your next project.

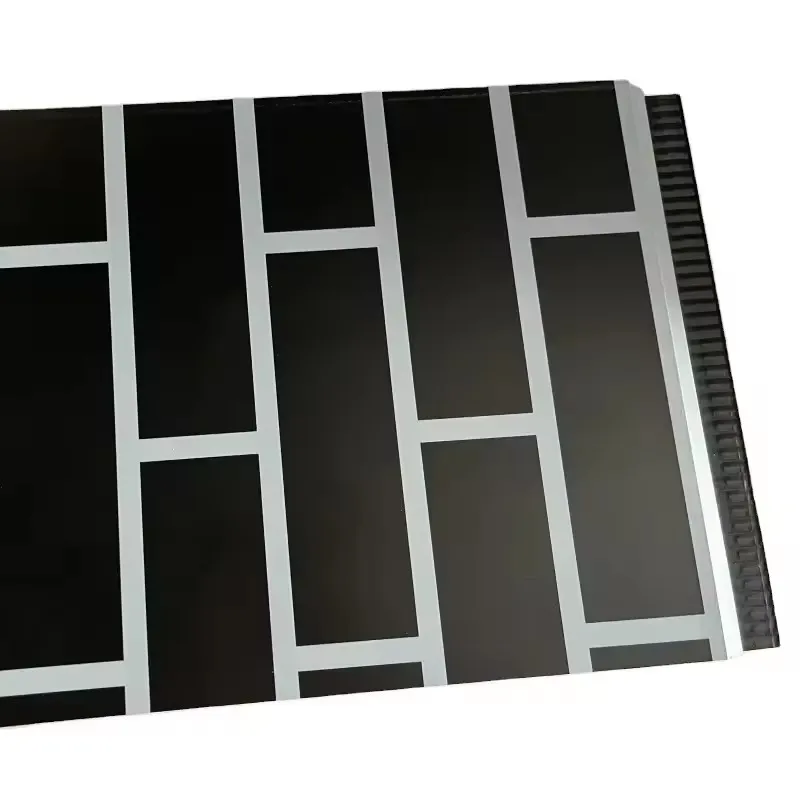

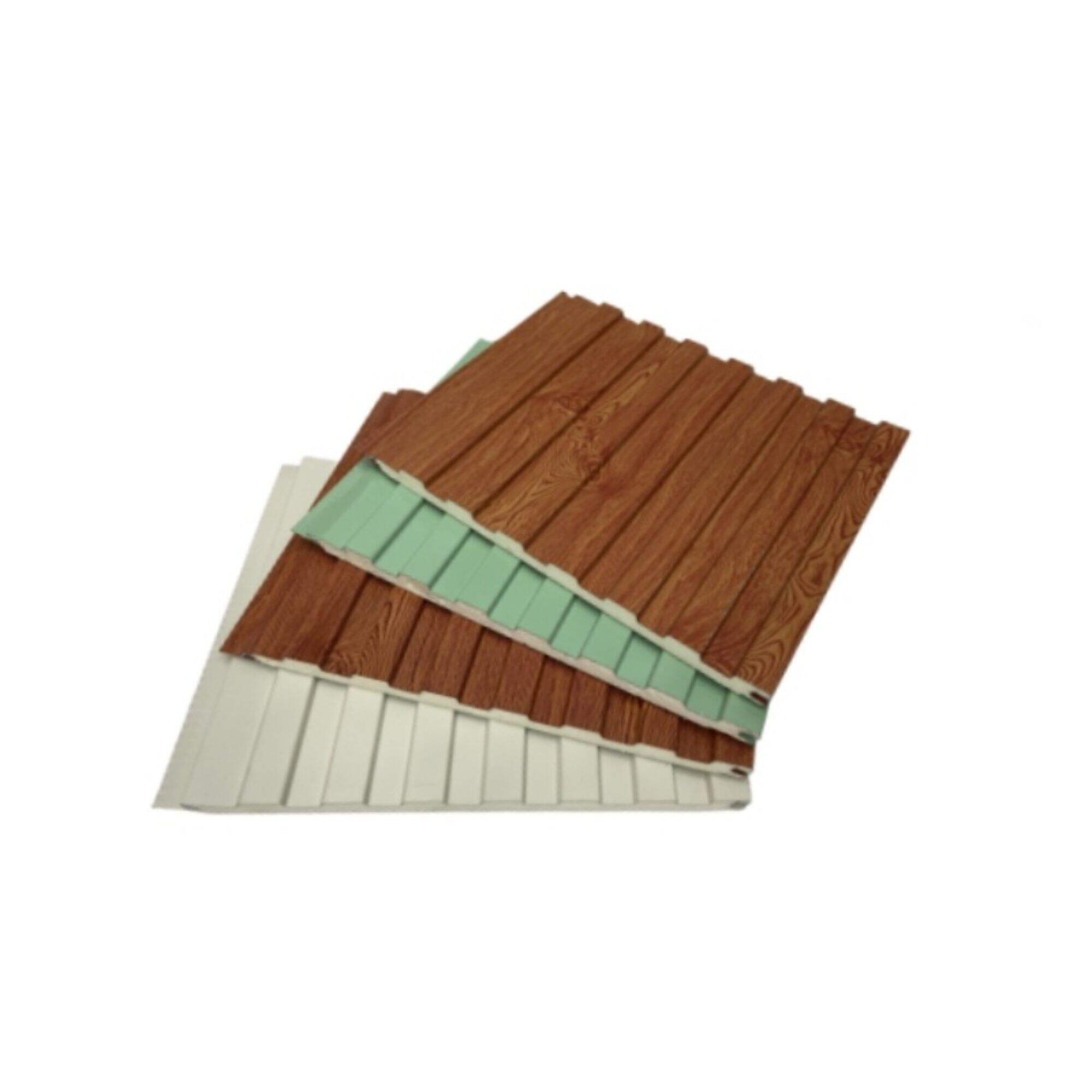

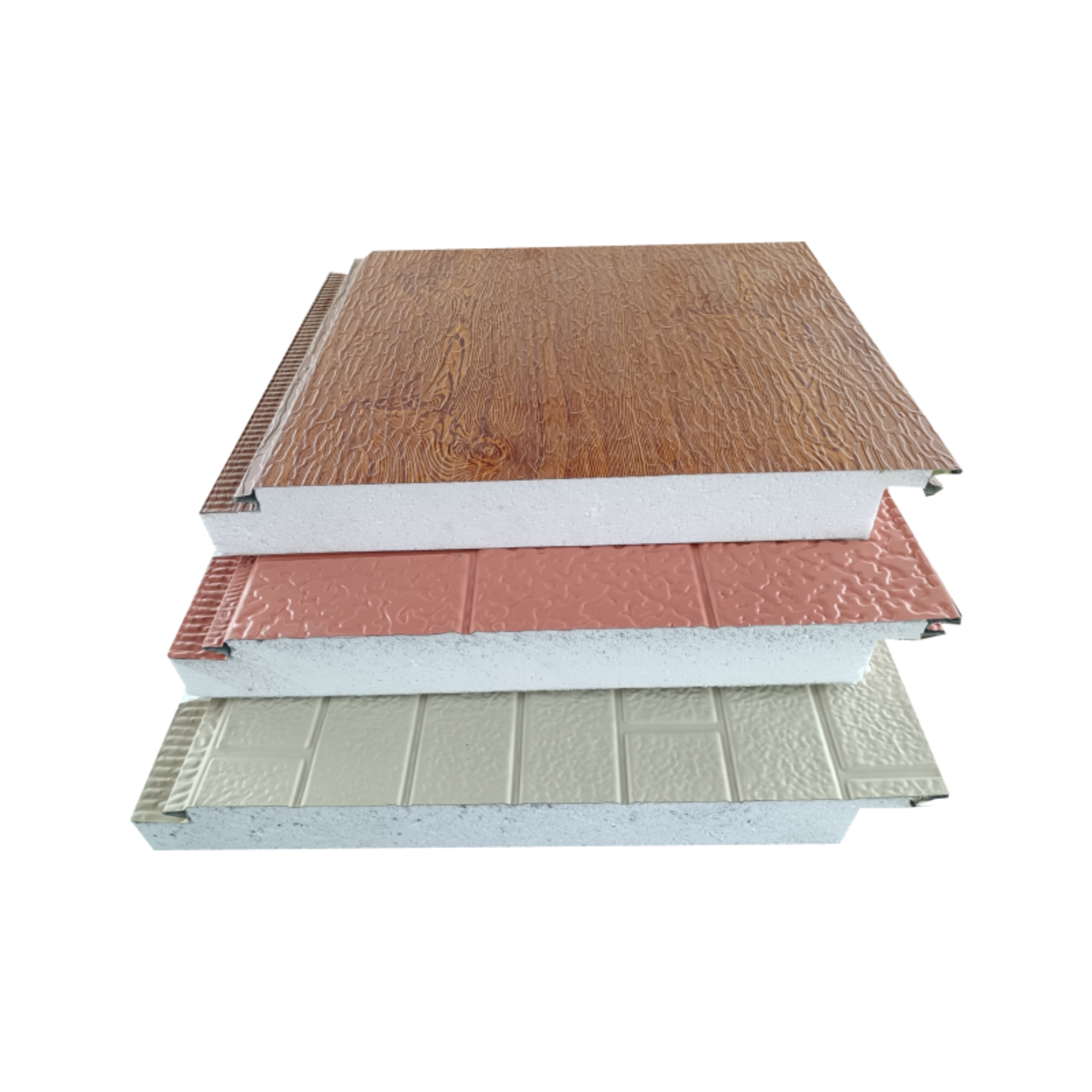

Our Metal Carved Panels: 383mm Fixed Width, Versatile Core Options

Metal carved panels are renowned for their aesthetic appeal, weather resistance, and structural strength, making them a top choice for exterior wall decoration and partition systems. Our panels are engineered with a fixed width of 383mm—a dimension optimized for easy installation, minimal material waste, and seamless splicing on-site. We offer three core material variants to cater to different functional needs:

Polyurethane (PU) Core Metal Carved Panels

PU cores boast excellent thermal insulation performance, low thermal conductivity, and high compressive strength. These panels are lightweight yet durable, effectively reducing building load while providing superior heat preservation. They are suitable for exterior walls of residential buildings, commercial complexes, and cold storage facilities, where energy efficiency is a priority.

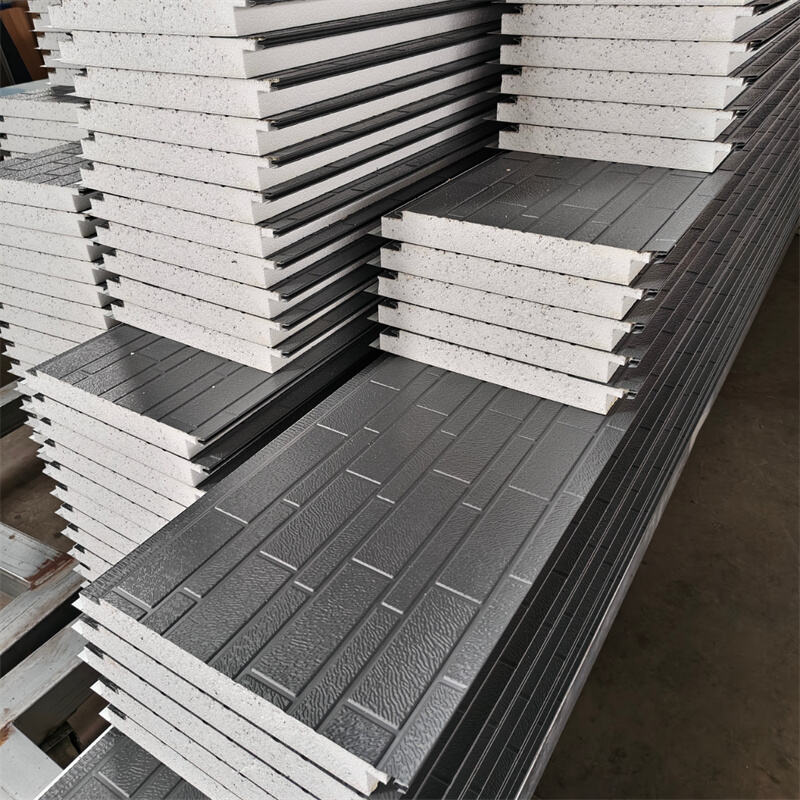

Foam Core Metal Carved Panels

Foam core panels offer a cost-effective solution with decent thermal insulation and sound absorption properties. They are easy to process and install, making them ideal for interior partitions, temporary construction sites, and low-rise building exteriors. The foam core is lightweight, ensuring hassle-free transportation and on-site handling.

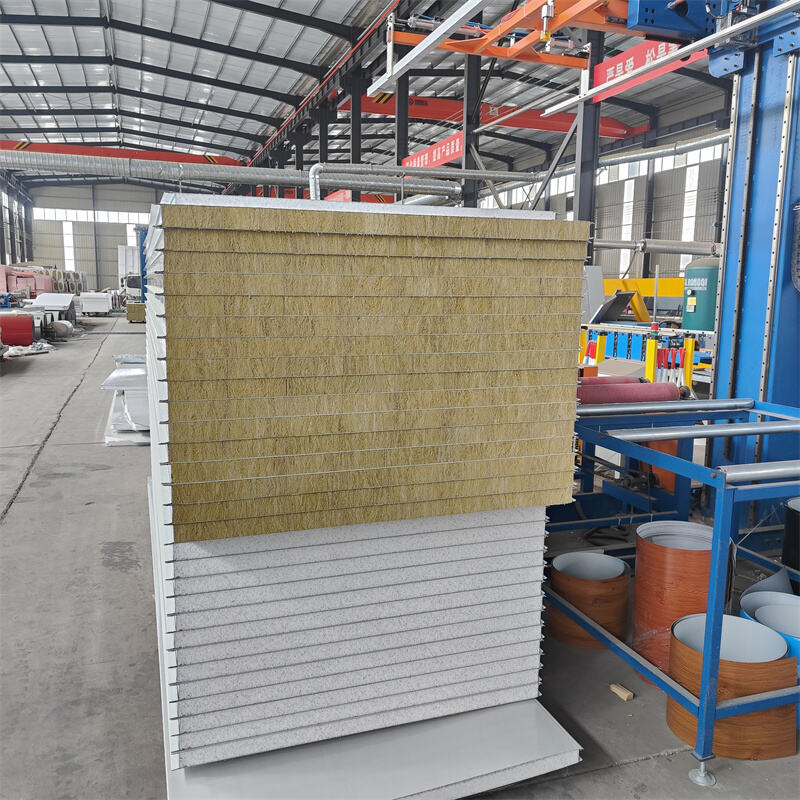

Rock Wool Core Metal Carved Panels

For projects requiring strict fire resistance and sound insulation, rock wool core panels are the go-to option. Rock wool is a non-combustible material that can withstand high temperatures, effectively preventing fire spread. It also has outstanding sound absorption capabilities, making these panels perfect for industrial factories, power plants, and public buildings with high fire safety standards.

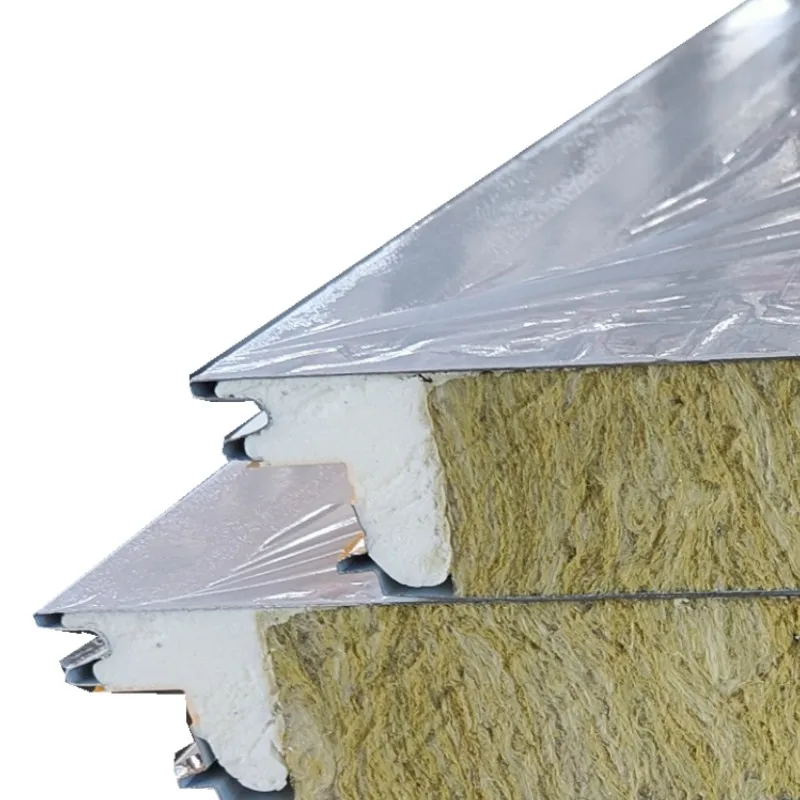

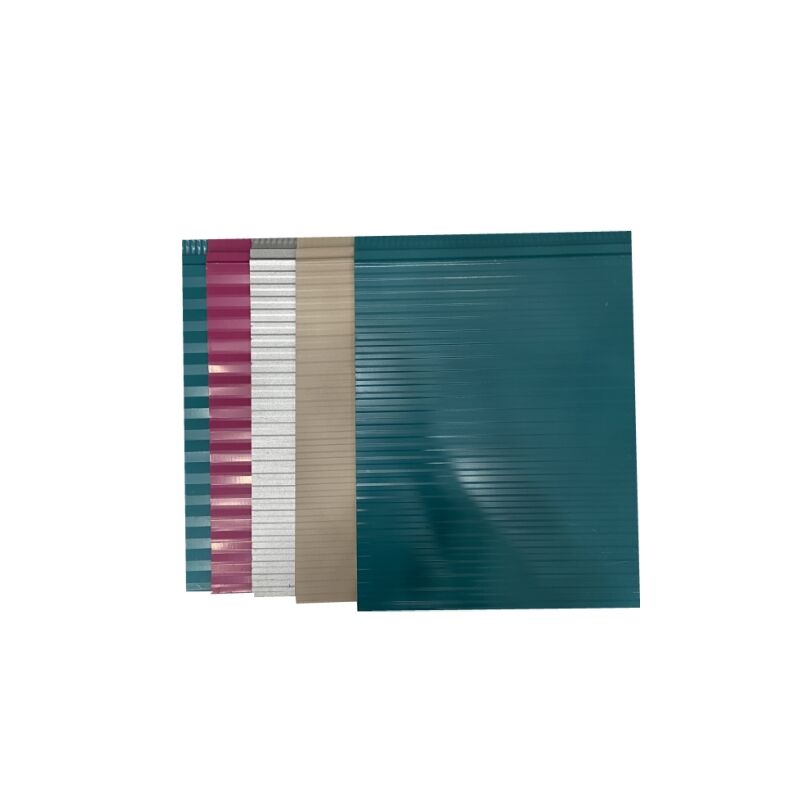

Cleanroom Panels: 1150mm Width, Conventional Foam & Rock Wool Cores

Cleanroom panels are essential components for building purification spaces such as pharmaceutical workshops, electronic manufacturing facilities, food processing plants, and laboratory cleanrooms. Our cleanroom panels feature a standard width of 1150mm, designed to maximize construction efficiency and meet the strict cleanliness and airtightness requirements of purification projects. We provide two core material options:

Foam Core Cleanroom Panels: These panels offer good thermal insulation and are cost-efficient, suitable for cleanrooms with moderate cleanliness requirements, such as food packaging workshops and general electronics assembly lines. The panels are smooth, easy to clean, and can maintain a dust-free environment effectively.

Rock Wool Core Cleanroom Panels: Engineered for high-standard purification and fire safety scenarios, these panels combine the advantages of rock wool’s fire resistance and sound insulation with the airtightness of cleanroom panels. They are ideal for pharmaceutical production GMP workshops, semiconductor manufacturing cleanrooms, and bio-laboratories, where fire prevention and contamination control are critical.

Why Choose Our Factory-Made Panels?

Customized Core Solutions: We offer a range of core materials to match different project budgets, functional requirements, and industry standards—from cost-saving foam cores to high-performance PU and fire-resistant rock wool cores.

Precision Dimensions: Fixed widths (383mm for metal carved panels, 1150mm for cleanroom panels) ensure consistent product quality and simplified on-site installation, reducing labor costs and construction time.

Rigorous Quality Control: Every batch of panels undergoes strict quality inspections, including tests for thermal insulation, fire resistance, and structural strength, to ensure compliance with international construction and purification standards.

One-Stop Manufacturing Services: As a direct factory, we provide OEM/ODM services, from material selection and panel design to production and delivery, offering competitive prices and flexible lead times for bulk orders.

Conclusion:

Whether you are undertaking an exterior wall cladding project, building industrial partitions, or constructing high-standard cleanroom facilities, our metal carved panels and cleanroom panels are reliable, high-performance choices. With fixed optimized widths and versatile core material options, our products can be tailored to meet the unique needs of your project. Contact our factory today to discuss your requirements, and let us provide you with the perfect building panel solutions!

Recommended Products

Hot News

-

Premium Metal Carved Panels & Cleanroom Panels: Customizable Core Materials for Industrial & Construction Needs

2025-12-25

-

Shandong Qigong Metal Engraving Panel Company launched the latest panel pattern at The 16th China Int'l Integrated Housing Industry &Building Industrialization Expo

2024-10-17

-

October 2023 Malaysia Building Materials Exhibition

2024-01-25

-

August 2023 Guangzhou Housing Expo

2024-01-06

-

June 2023 Foreign Customers Visit The Factory

2024-01-06

-

April 2023 Canton Fair

2024-01-06

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

HY

HY