Polyurethane (PU) Sandwich Panels Lead Modern Construction with Superior Insulation & Versatile Applications

In today’s fast‑developing construction and building decoration industry, energy efficiency, structural stability, and installation efficiency have become core requirements for architects, contractors, and project investors. Polyurethane (PU) sandwich panels — as a high‑performance building board — are increasingly becoming the preferred solution for modern construction projects worldwide.

Outstanding Performance Features of PU Sandwich Panels

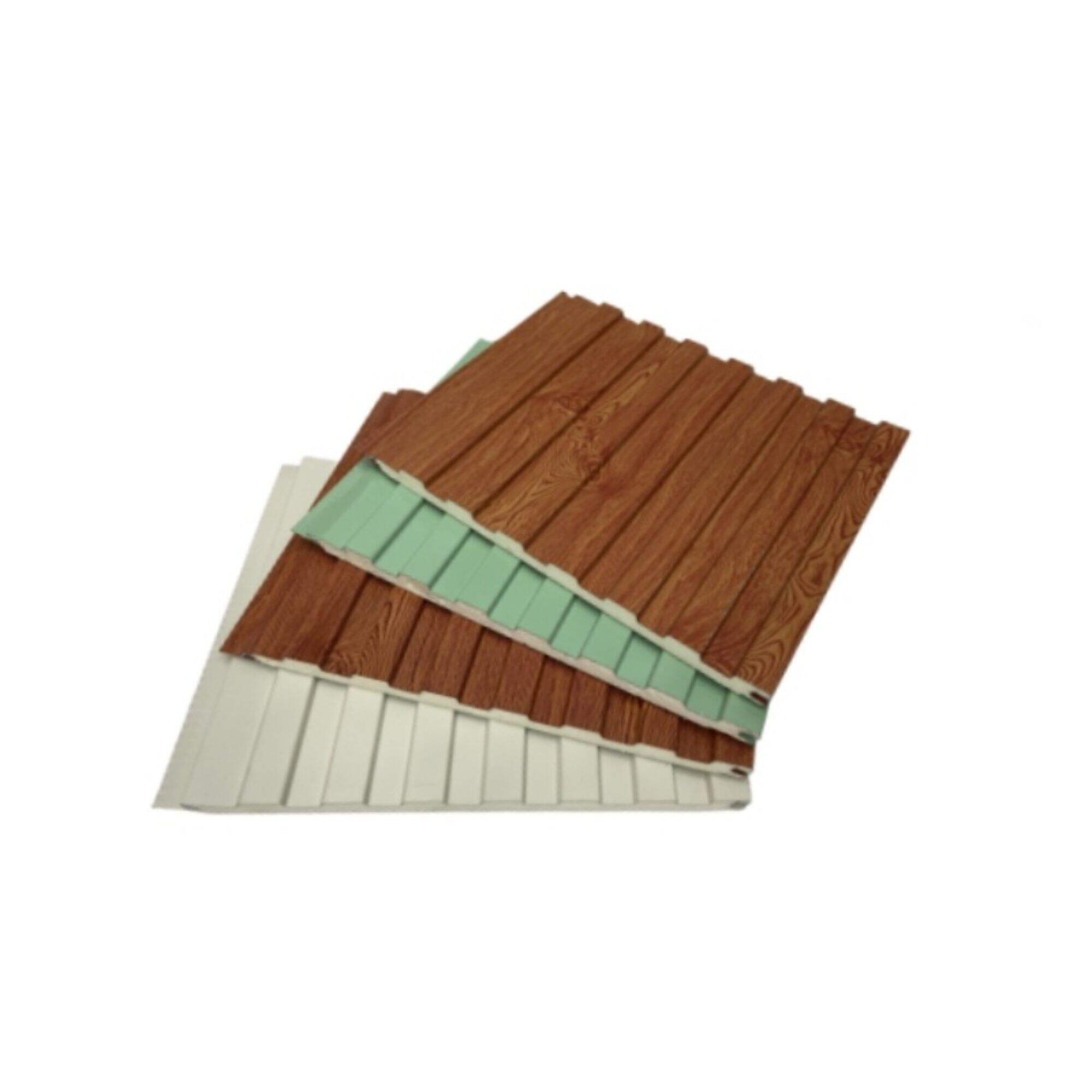

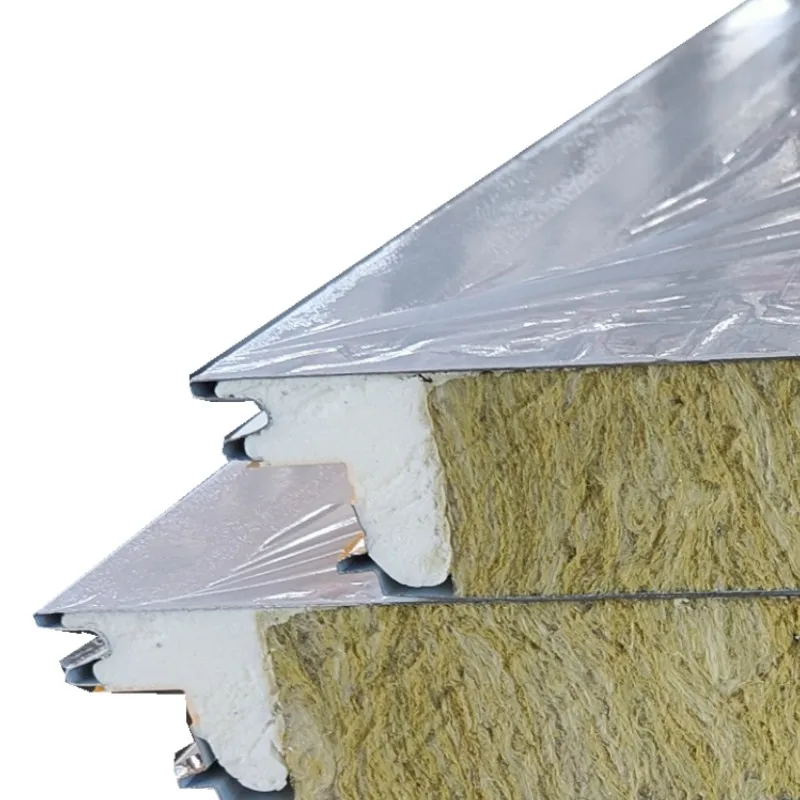

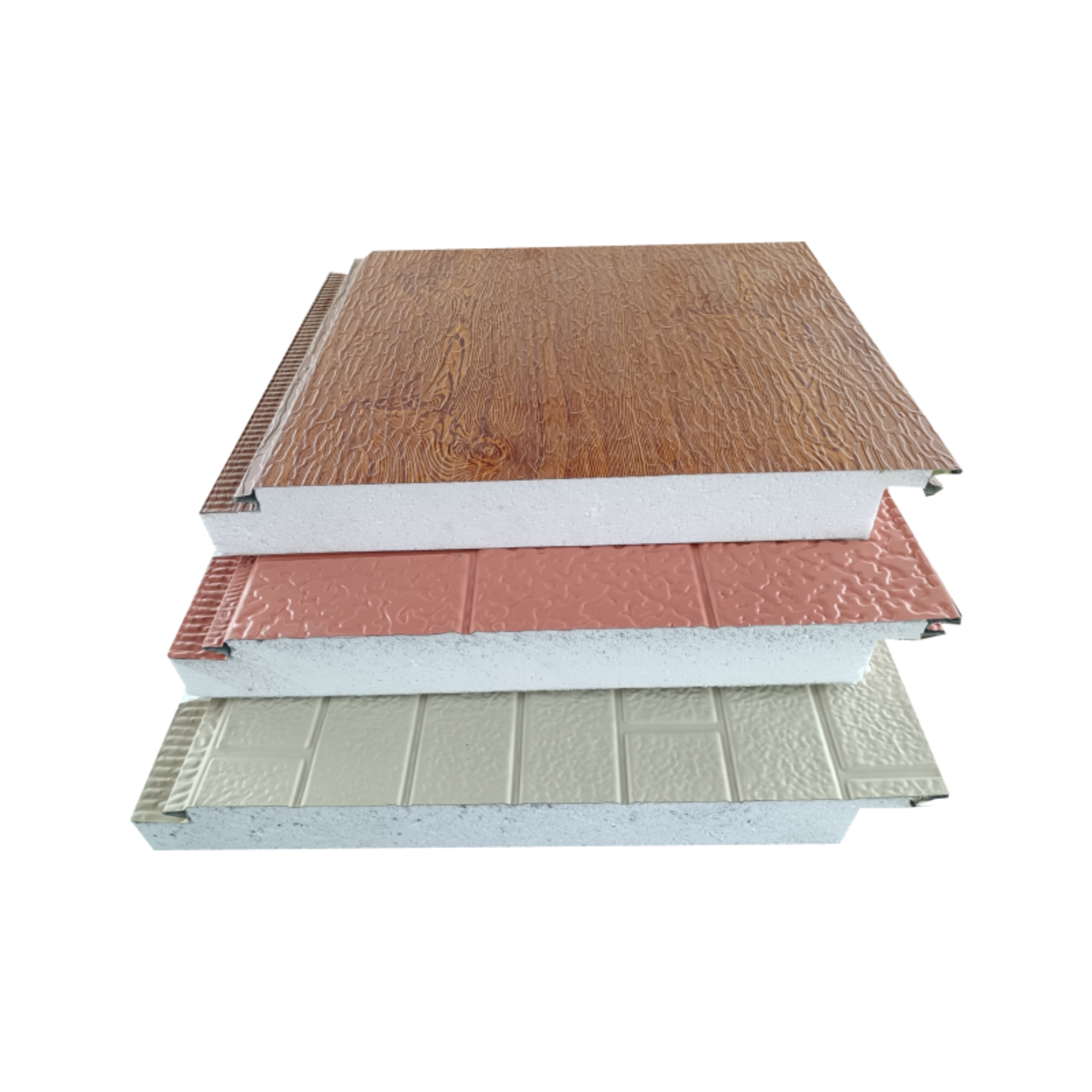

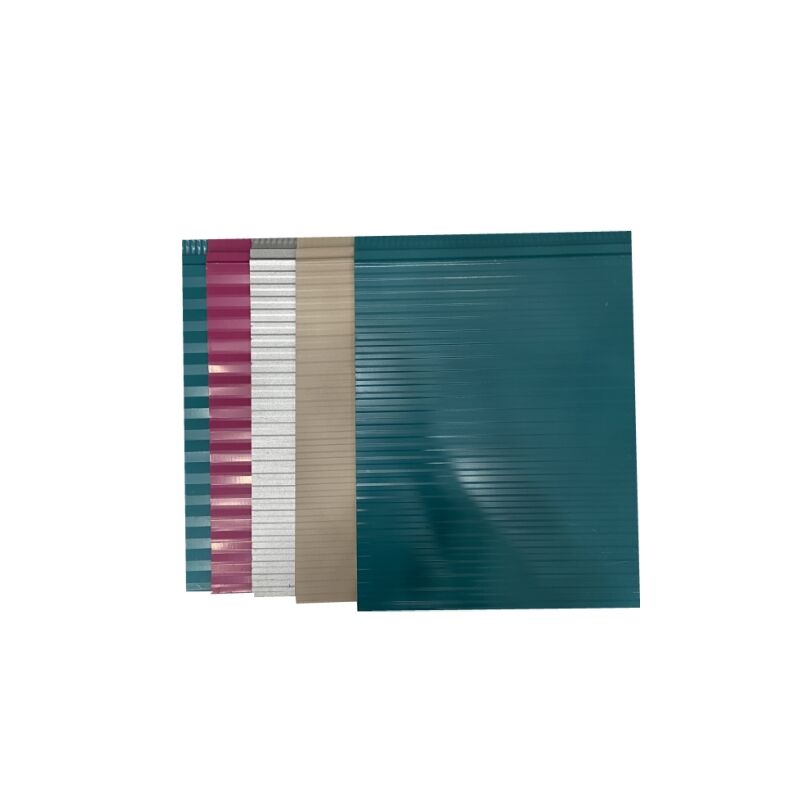

Our polyurethane sandwich panels are composed of high‑strength metal face sheets and a dense PU core material, forming an integrated structural panel with multiple advantages:

Excellent Thermal Insulation

The closed‑cell structure of polyurethane delivers ultra‑low thermal conductivity, greatly reducing heat transfer. This helps maintain stable indoor temperatures, lower air‑conditioning and heating energy consumption, and achieve long‑term cost savings.

Lightweight but High Strength

PU sandwich panels are lightweight while maintaining strong mechanical properties, including pressure resistance, impact resistance, and structural stability. They reduce the overall load of buildings and support safer, faster construction.

Short Installation Time & Labor Savings

The integrated molding design allows for direct cutting and fixing on‑site. Compared with traditional construction materials, PU sandwich panels greatly shorten construction cycles, reduce labor costs, and minimize on‑site waste.

Good Sound Insulation & Moisture Resistance

The PU core effectively blocks noise transmission and resists moisture and mildew, making it ideal for environments requiring dryness and quietness.

Long Service Life & Low Maintenance

With weather, corrosion, and deformation resistance, our polyurethane sandwich panels maintain stable performance and appearance for years, requiring little maintenance.

Wide Applications of Polyurethane Sandwich Panels

Thanks to their balanced performance, PU sandwich panels are widely used in various fields:

Industrial Workshops & Warehouses

Ideal for factory buildings, logistics centers, and warehouses demanding thermal insulation, fireproof performance, and quick construction.

Prefabricated & Modular Buildings

Commonly used in prefab houses, container houses, temporary offices, and camp buildings for portability and efficiency.

Commercial & Public Buildings

Suitable for shopping malls, stadiums, stations, and exhibition halls that need aesthetic appearance and reliable performance.

Cold Chain & Cold Storage Construction

Excellent thermal insulation makes PU panels a standard material for low‑temperature warehouses, cold rooms, and food processing facilities.

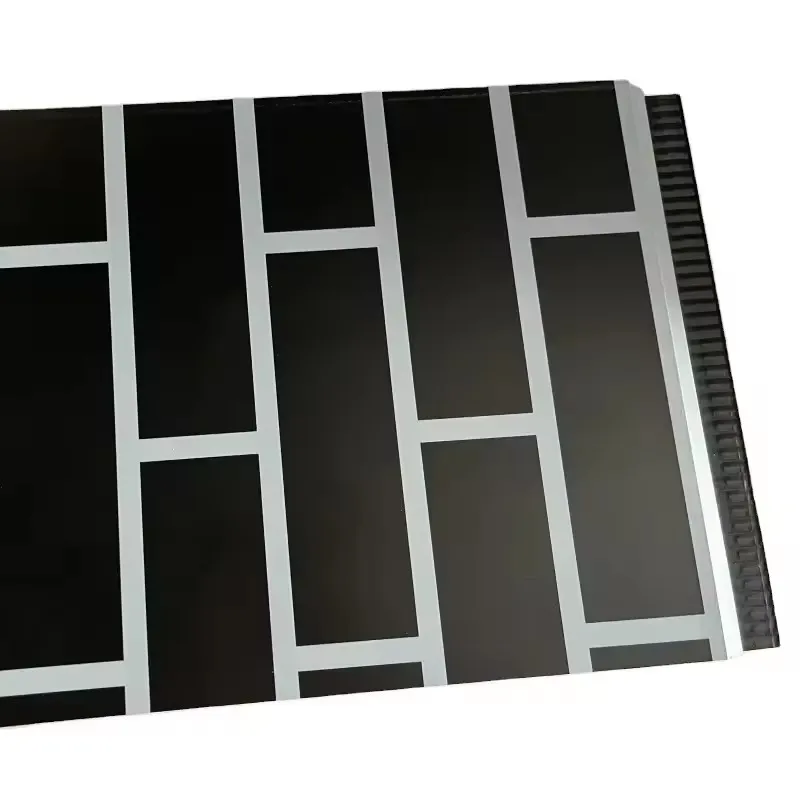

Exterior Wall Cladding & Decoration

Used as decorative and energy‑saving wall panels for residential and public buildings, combining appearance and practicality.

Our Commitment to Quality

We strictly control production standards to ensure each polyurethane sandwich panel meets international performance requirements in thermal insulation, strength, and durability. We also support customized specifications to match different project designs.

Conclusion

As green and energy‑efficient construction continues to develop, polyurethane sandwich panels will remain a key material in modern construction. Whether for industrial construction, cold storage, prefab housing, or exterior wall systems, PU sandwich panels provide reliable, economical, and sustainable solutions.

For more information about our polyurethane sandwich panels, metal carved boards, rock wool sandwich panels, or 1150mm cleanroom panels, welcome to visit our product page or contact our sales team.

Recommended Products

Hot News

-

Premium Metal Carved Panels & Cleanroom Panels: Customizable Core Materials for Industrial & Construction Needs

2025-12-25

-

Shandong Qigong Metal Engraving Panel Company launched the latest panel pattern at The 16th China Int'l Integrated Housing Industry &Building Industrialization Expo

2024-10-17

-

October 2023 Malaysia Building Materials Exhibition

2024-01-25

-

August 2023 Guangzhou Housing Expo

2024-01-06

-

June 2023 Foreign Customers Visit The Factory

2024-01-06

-

April 2023 Canton Fair

2024-01-06

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

HY

HY