- Overview

- Product Description

- Inquiry

- Related Products

Product Description

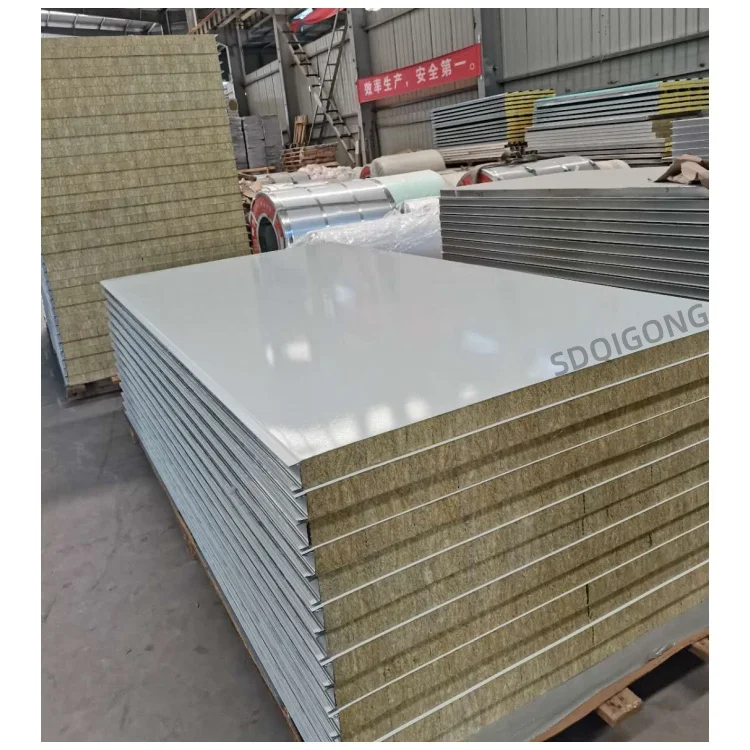

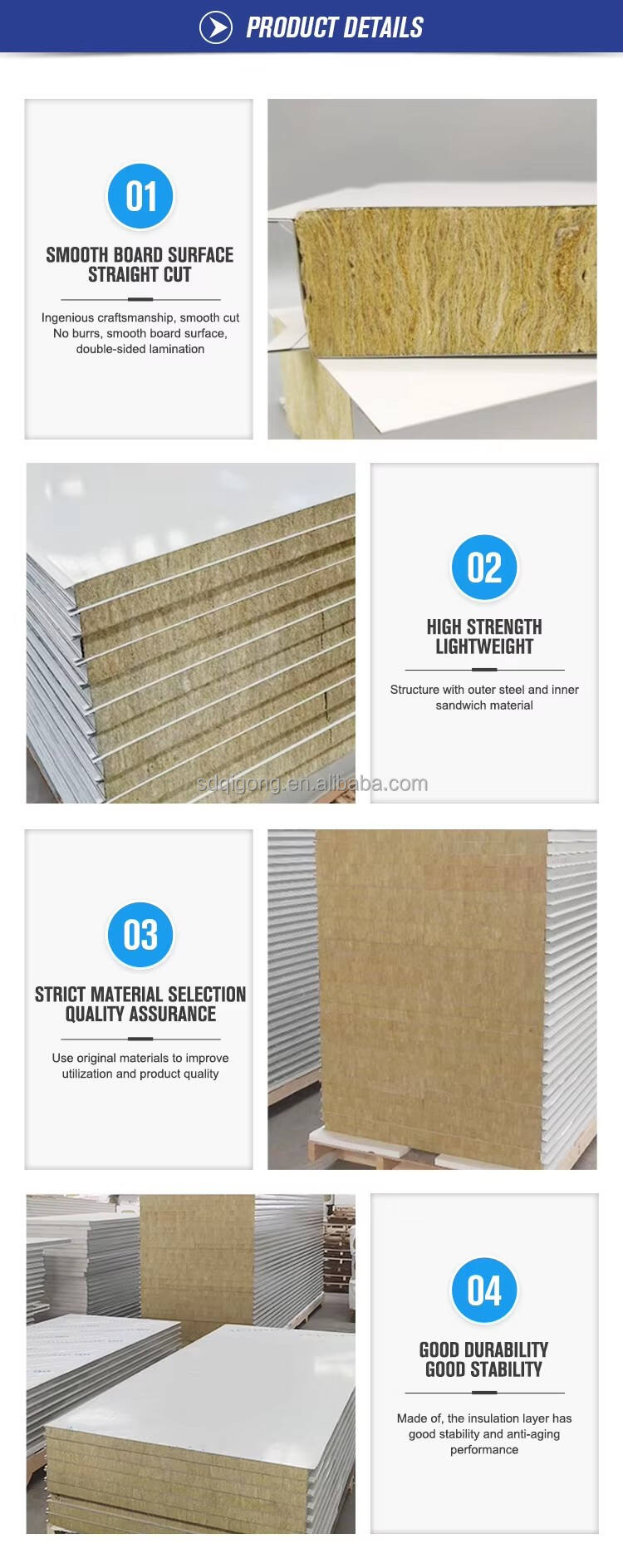

Introducing, the SDQIGONG’s Clean Room Rock Wool Sandwich Wall Panels, a top-of-the-line solution for all your purification needs. These SIP foam panels are specially designed to provide maximum insulation and protection in clean room environments.

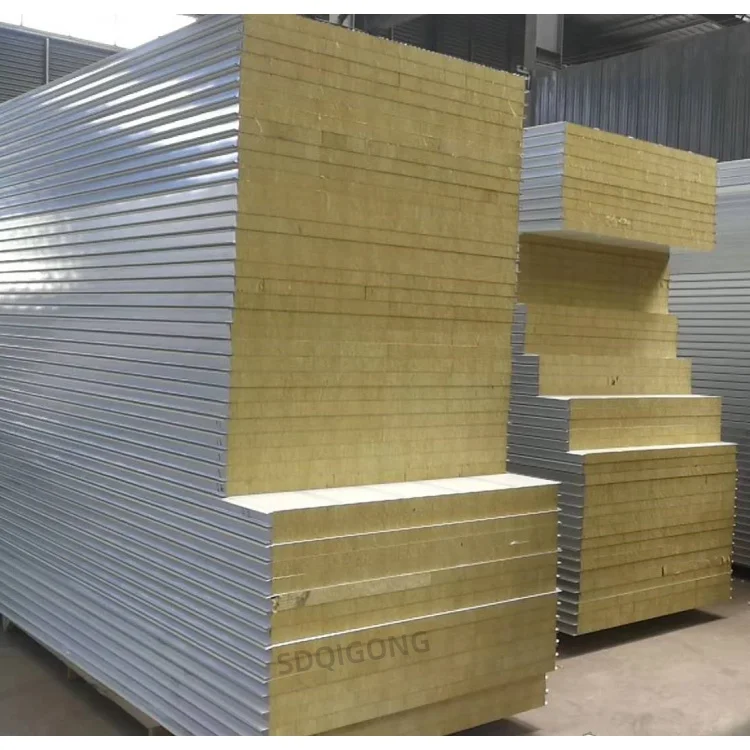

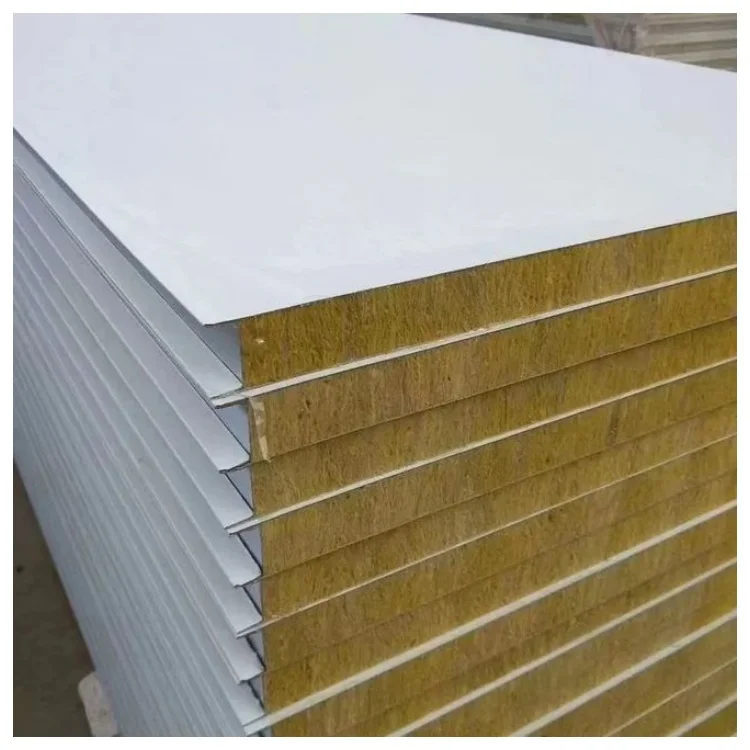

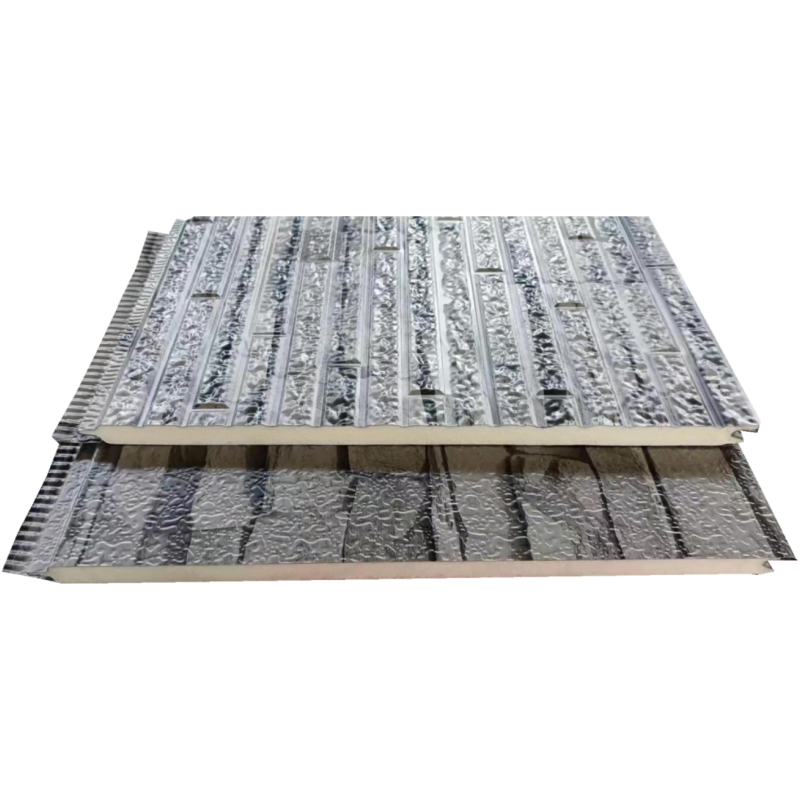

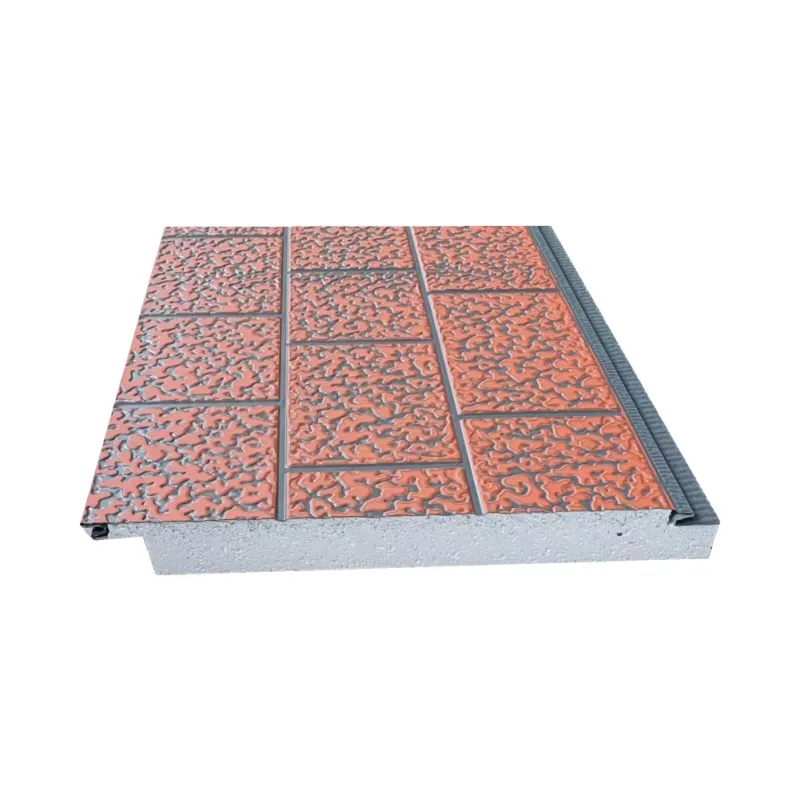

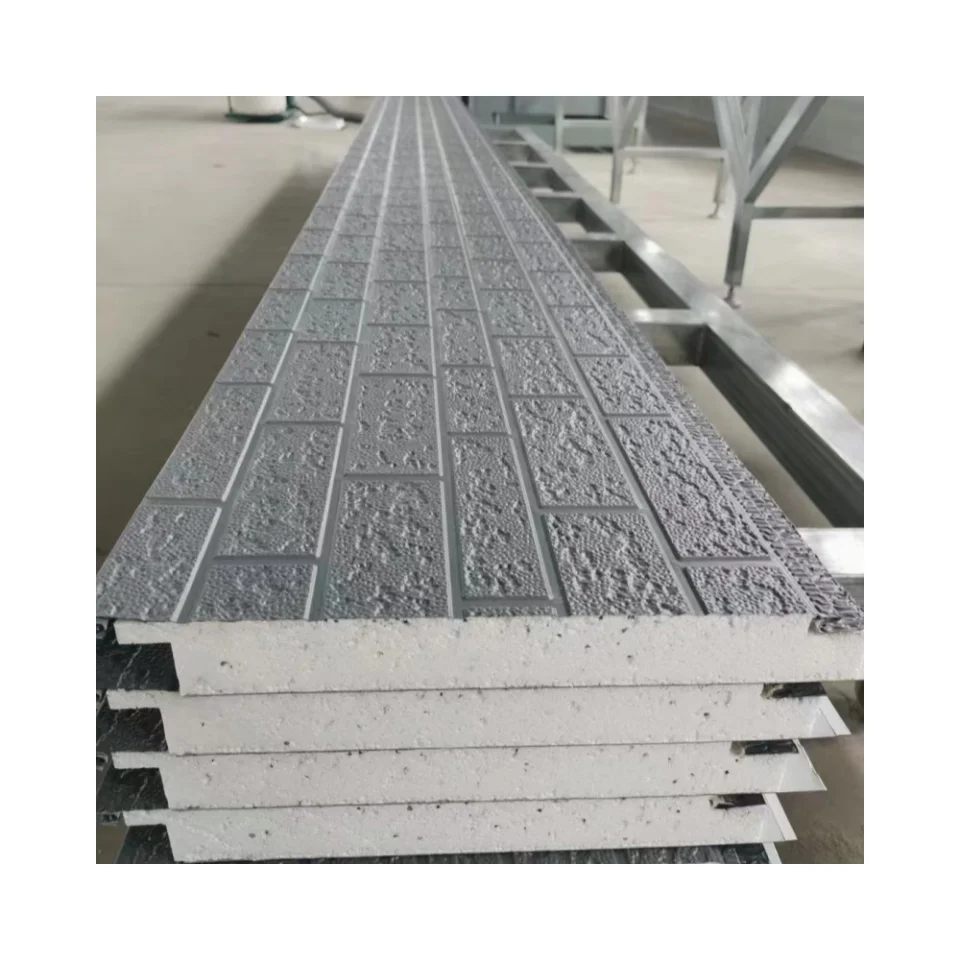

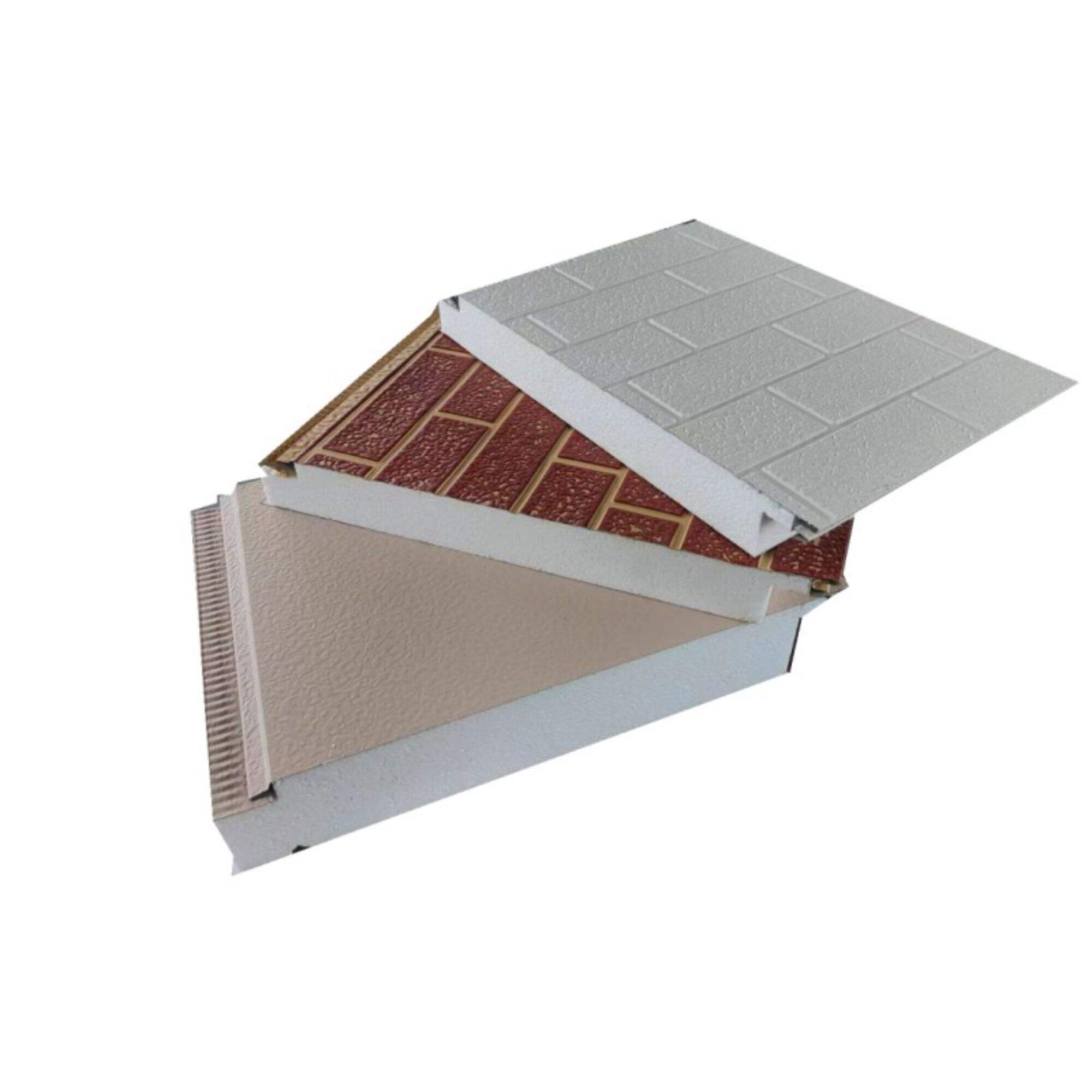

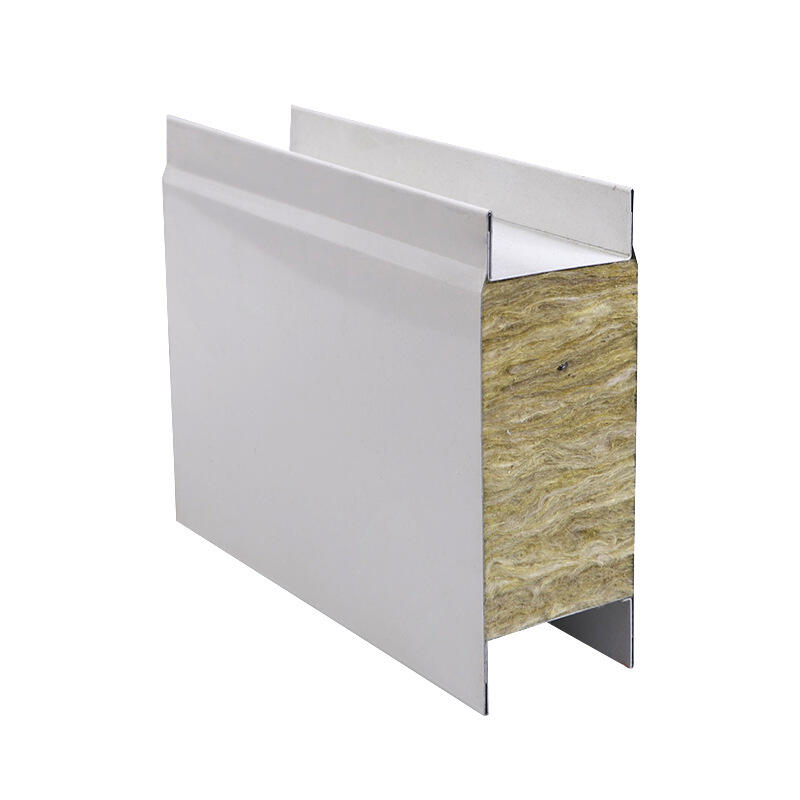

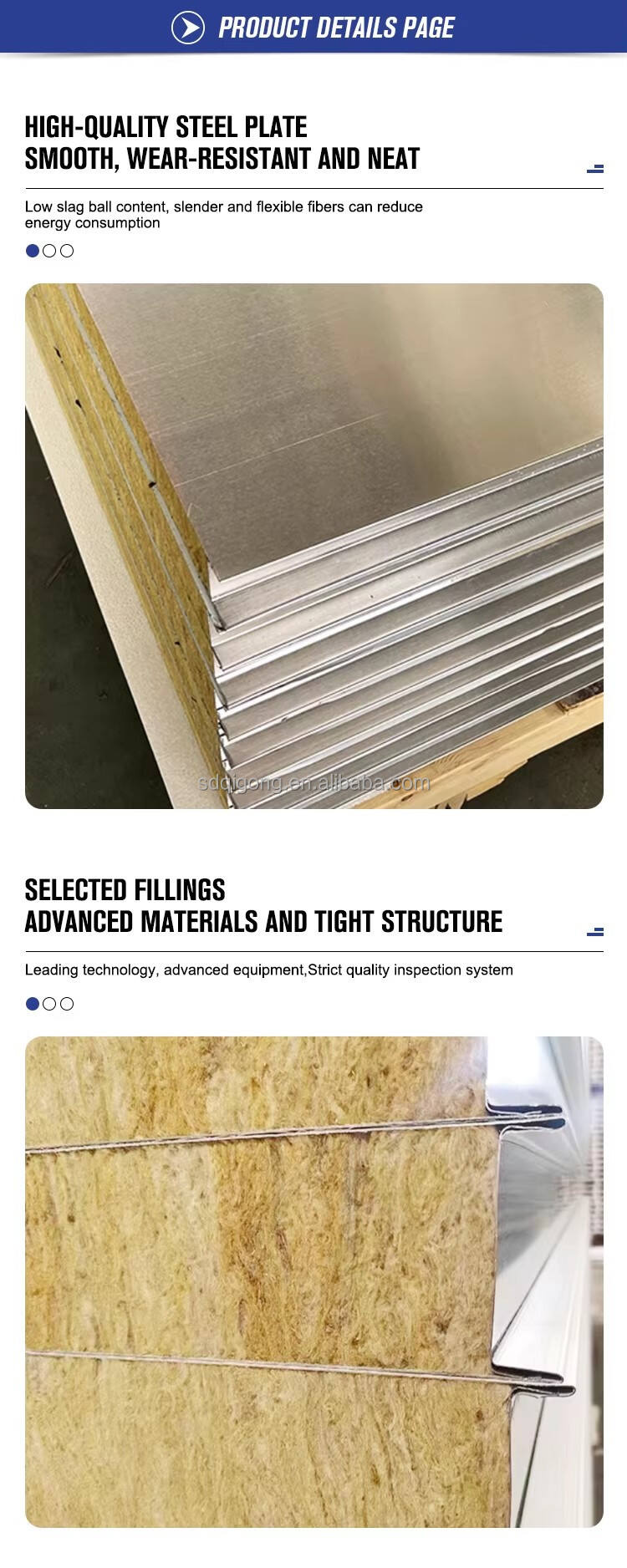

Our sandwich wall panels are made from high-quality rock wool, a natural mineral fiber that is known for its excellent thermal insulation properties. The rock wool core is encased in two layers of sturdy metal sheets, creating a sandwich-like structure that offers superior durability and performance.

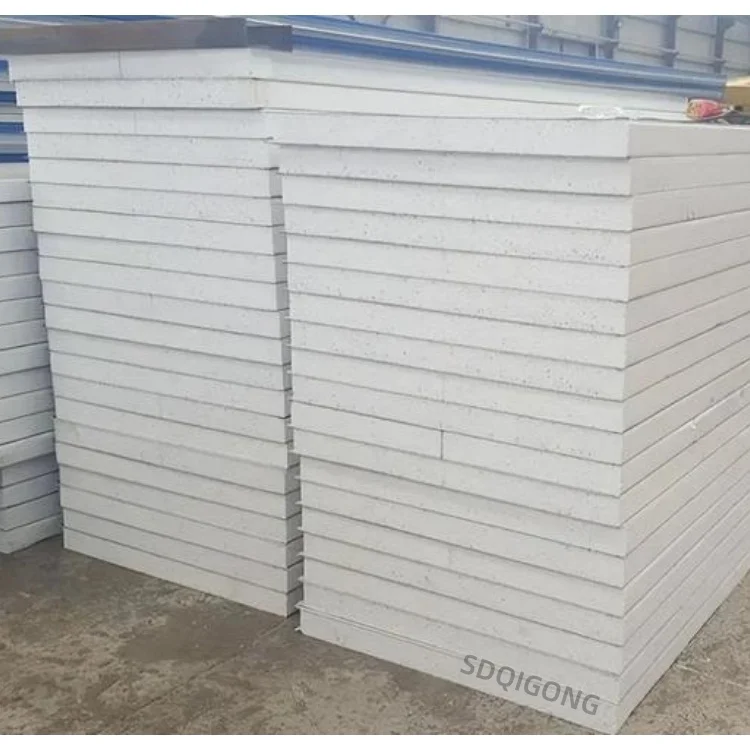

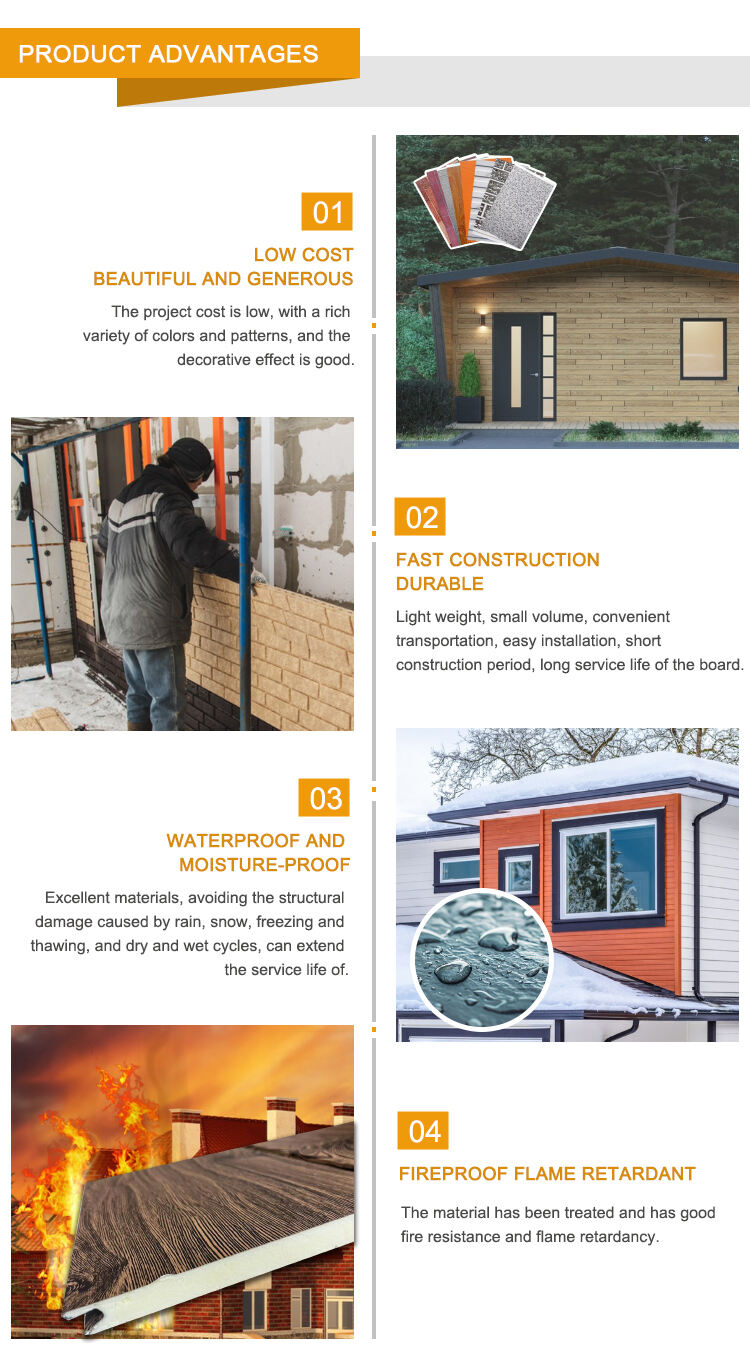

The SDQIGONG’s Clean Room Rock Wool Sandwich Wall Panels are not only highly efficient in maintaining a controlled environment, but they are also easy to install and maintain. The lightweight design of these panels makes them ideal for quick and hassle-free installations in clean rooms of all sizes.

One of the standout features of our purification board is its ability to effectively isolate sound and reduce noise levels, creating a quiet and peaceful working environment. This is essential for clean rooms where precision and focus are of utmost importance.

In addition to their exceptional thermal insulation and soundproofing capabilities, our SIP foam panels are also fire-resistant, providing an added layer of safety and protection. With the SDQIGONG’s Clean Room Rock Wool Sandwich Wall Panels, you can have peace of mind knowing that your clean room is shielded from potential fire hazards.

Whether you are looking to upgrade an existing clean room or build a new one from scratch, the SDQIGONG’s Clean Room Rock Wool Sandwich Wall Panels are the perfect solution. They are versatile, durable, and reliable, ensuring that your clean room stays clean, safe, and efficient at all times.

Invest in the best with SDQIGONG’s Clean Room Rock Wool Sandwich Wall Panels. Upgrade your clean room today and experience the difference in quality and performance. Trust in SDQIGONG for all your purification needs

Sandwich panels generally consist of two outer metal sheets (steel or aluminum) with an insulation core sandwiched between them. The metal sheets are bonded to the insulation core with specialized adhesives. As the product is pre-fabricated in the factory, Rock wool core sandwich panels have been used successfully employed in various fast track construction projects

Product name |

Mechanism rock wool cleaning board |

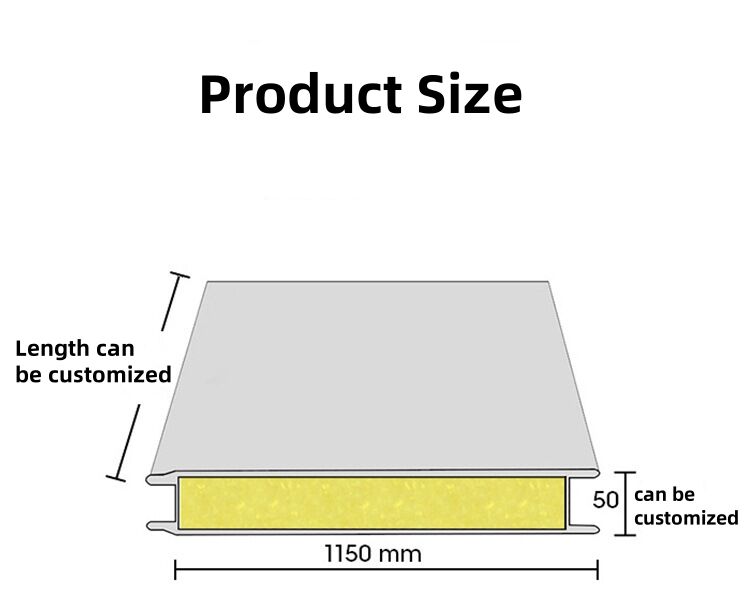

Thickness |

50mm/75mm/100mm |

Length |

According to customer's request |

Width |

950mm/1150mm |

Materials |

color coated steel plate+rock wool - Surface coating |

Steel plate thickness |

Both sides are 0.4mm |

Fire rating |

A Level |

Density |

100kg/m³ |

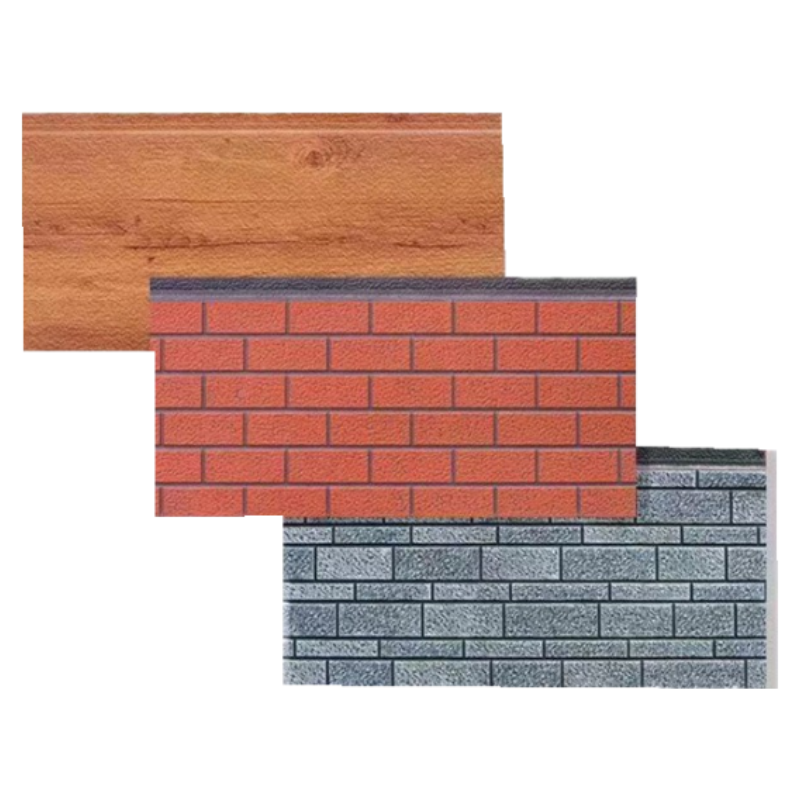

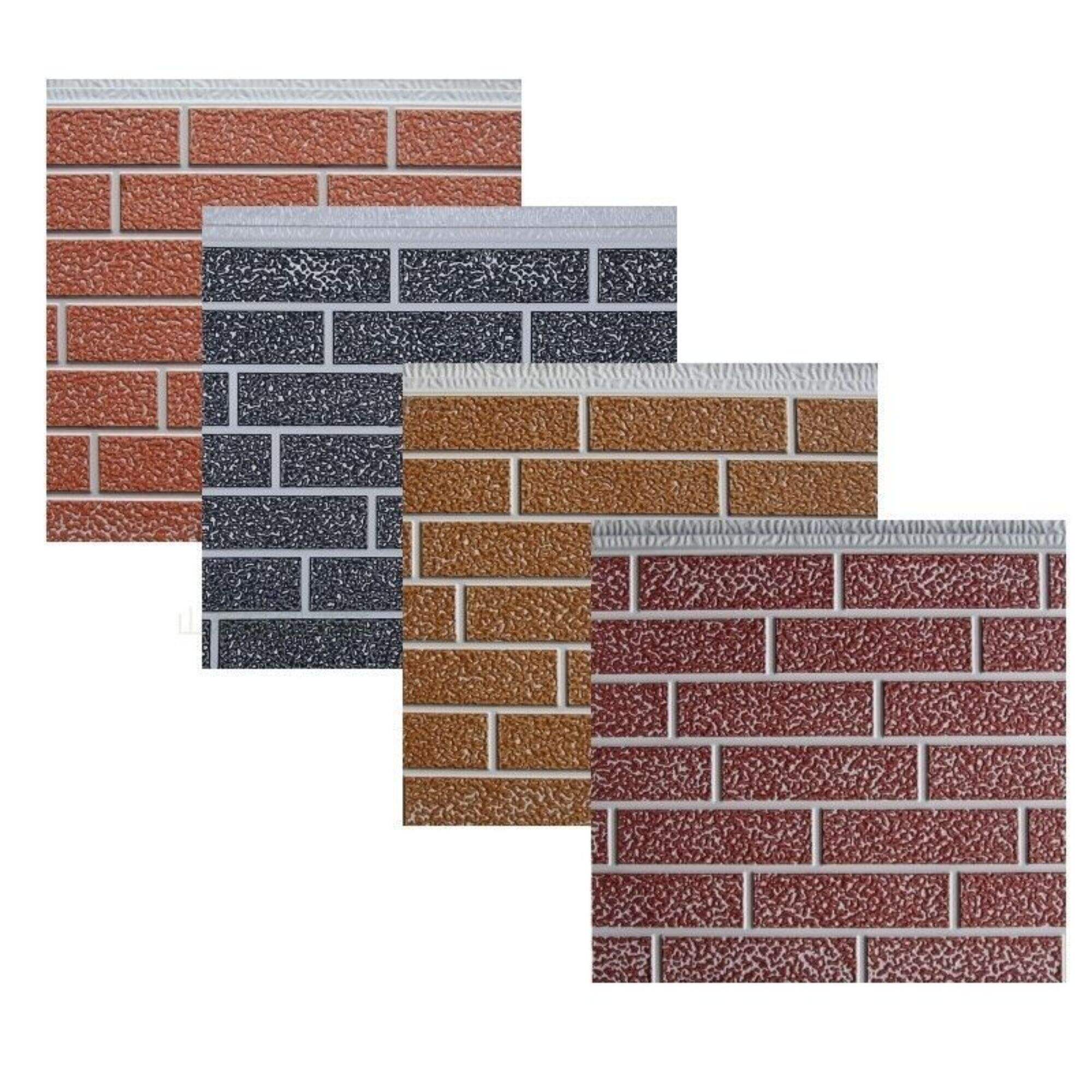

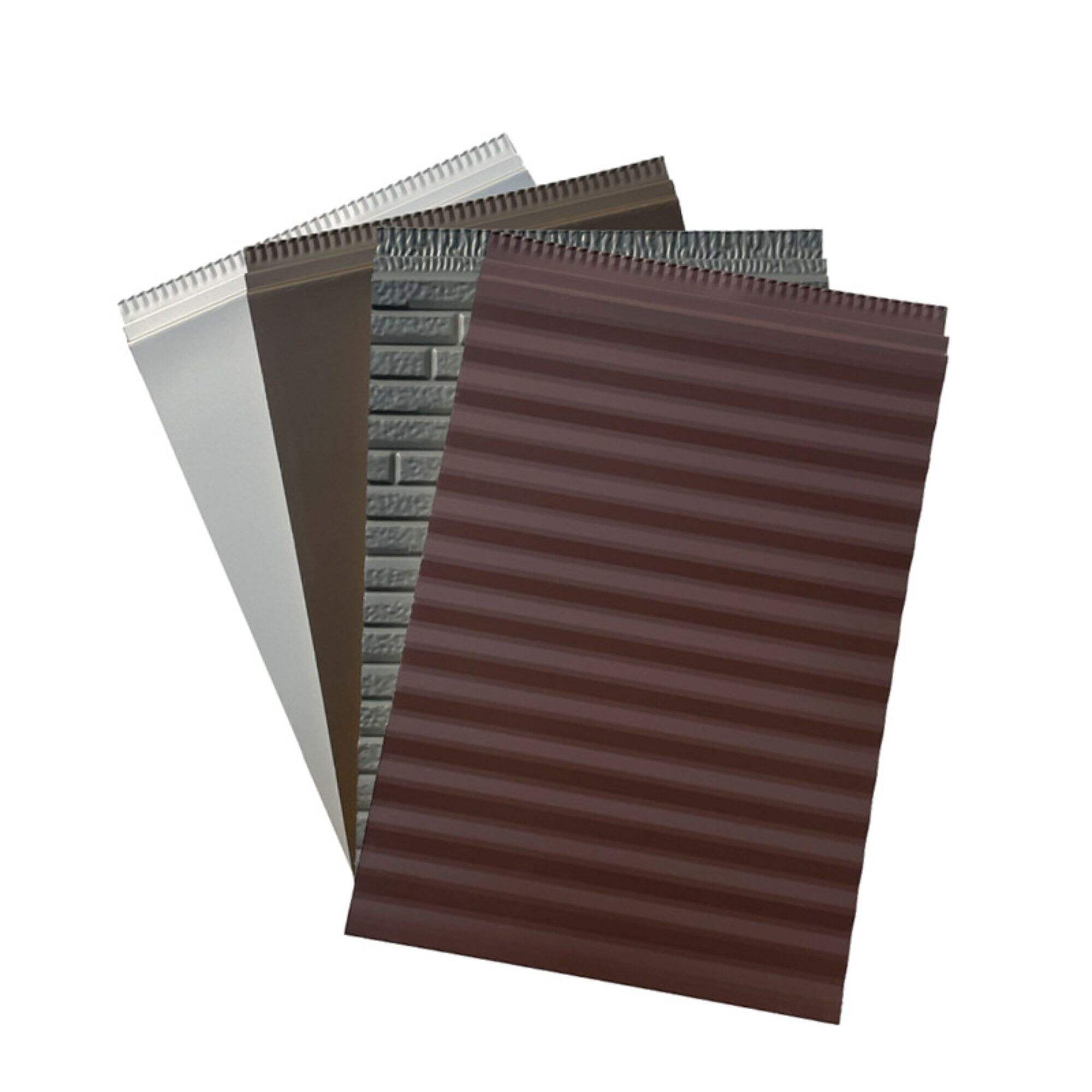

Color |

White, Gray, etc |

Application |

Food industry, Electronics industry, Biological industry, Medical industry, Chemical industry, Research industry, Pharmaceutical industry, New energy industry, Aviation industry |

2. Purify the air: Rock wool purification boards have a good air purification effect and can absorb air. It improves indoor air quality and protects people’ s health by removing pollutants, odors and bacteria, etc

3. Good fireproof performance: The rock wool purification board has excellent fireproof performance and does not produce harmful gases at high temperatures. Effectively prevent the spread of fire and ensure the safety of life and property

4. Long service life: The rock wool purification board material has excellent raw material quality, requires less water for production and has good molding effect. The board surface is smooth, high hardness, not easy to deform, crack and crack, and has a long service life

5. Easy installation: The disadvantage of rock wool purification board is that it is relatively fragile and needs to be protected from force and impact. However, due to its lightweight, standard size and regular shape, the installation process is simple and fast, reducing the difficulty and construction period of construction

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

HY

HY