Horizontal Installation Decoration 16mm Thickness Interior Exterior Wall Insulated Polyurethane Foam Sandwich Panel for House

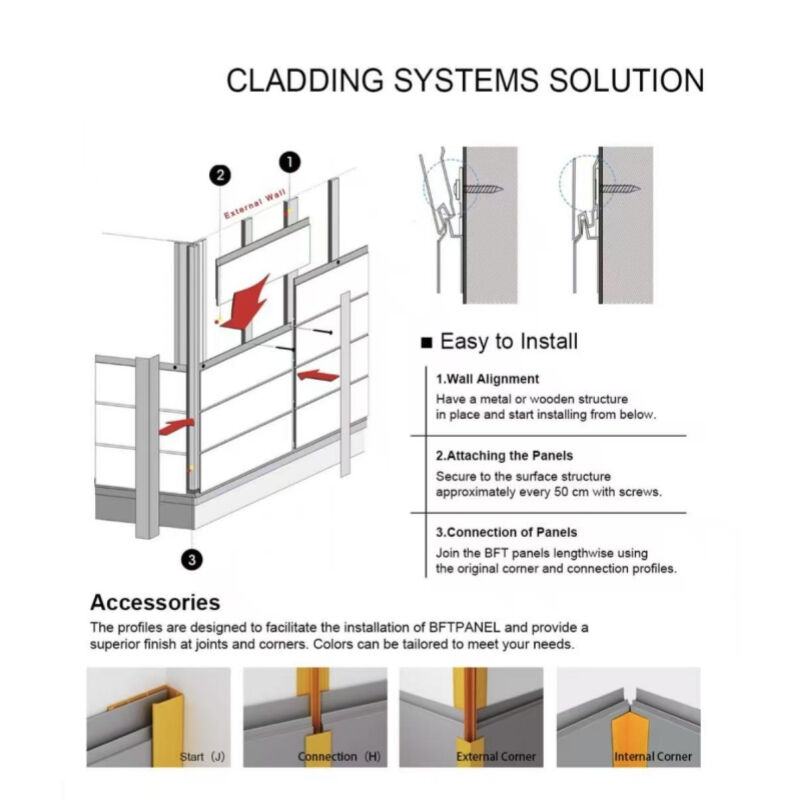

We operate our own factory with 4 production lines, capable of manufacturing 10,000㎡ per day to ensure timely delivery and competitive pricing. Choose from hundreds of ready-made patterns or provide your own design/RAL color code for fully customized finishes. Two workers can install up to 300㎡ per day thanks to the smart groove joint system and concealed screw design — no visible screws or exposed fasteners.

MOQ: 1,500㎡ (suitable for 20ft container)

- Overview

- Product Description

- Product Parameter

- Product Advantages

- Application Scenarios

- FAQ

- Inquiry

- Related Products

Product Description

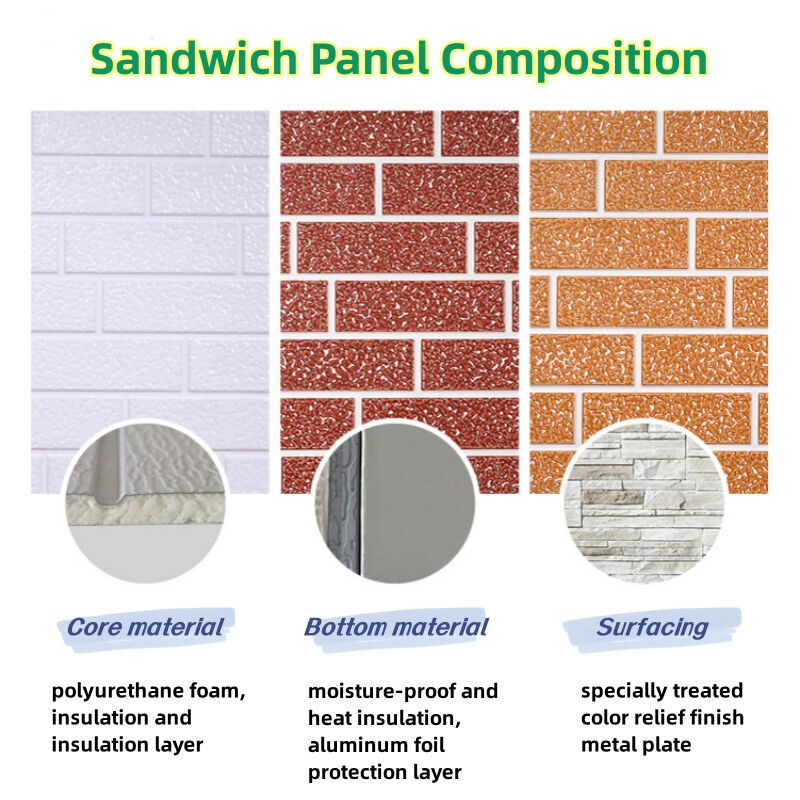

Polyurethane Core Metal Carved Sandwich Panels: Combining Aesthetics with Performance

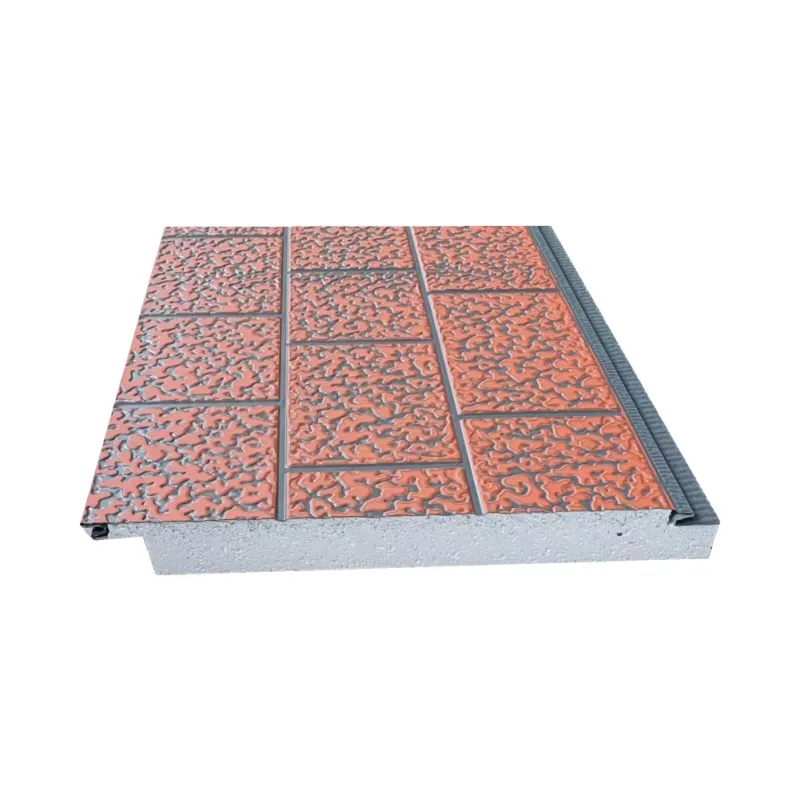

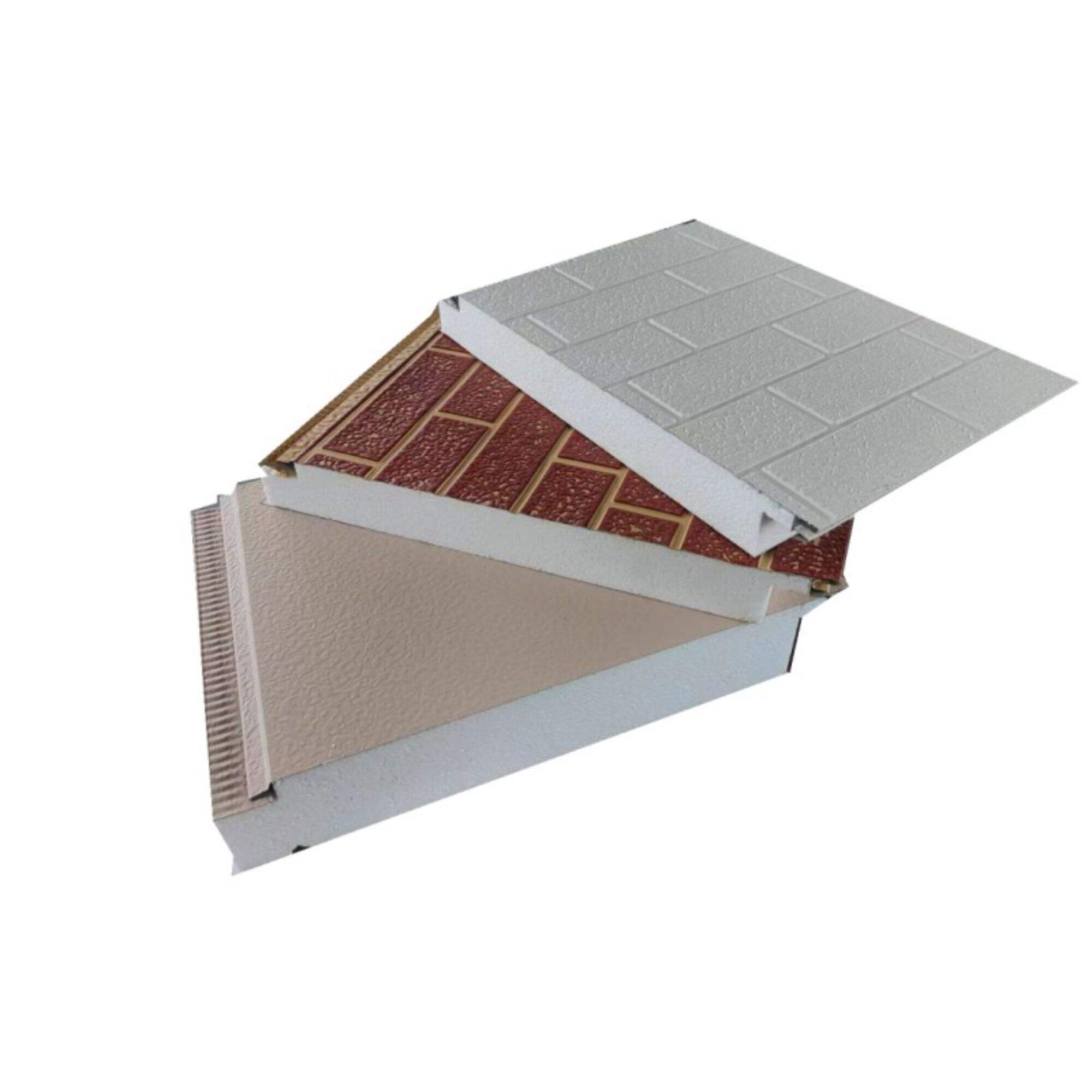

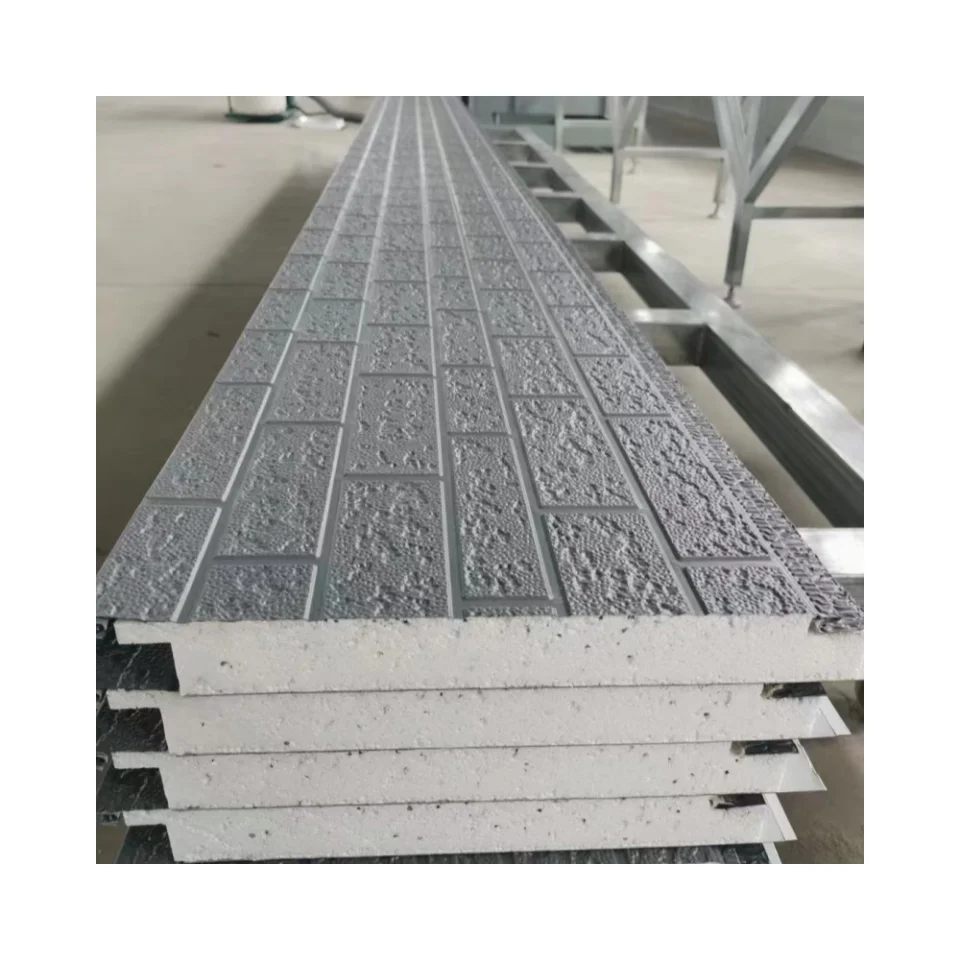

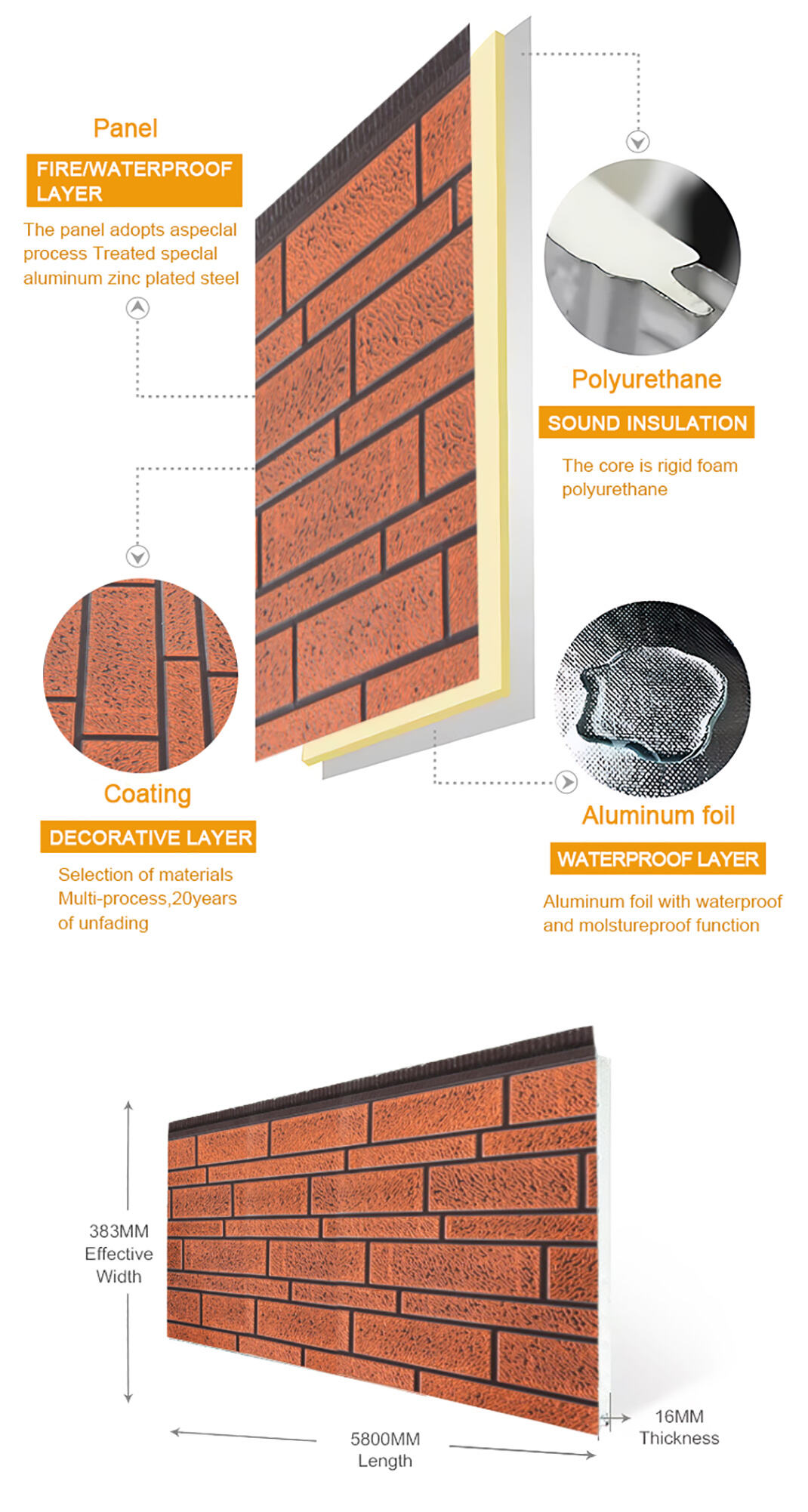

Metal carved sandwich panels with a rigid polyurethane (PU) insulation core represent a significant advancement in modern building envelope solutions. These composite panels integrate the visual appeal of intricately embossed metal facings – the defining feature of metal carved boards – with the exceptional thermal efficiency of PU core sandwich panels.

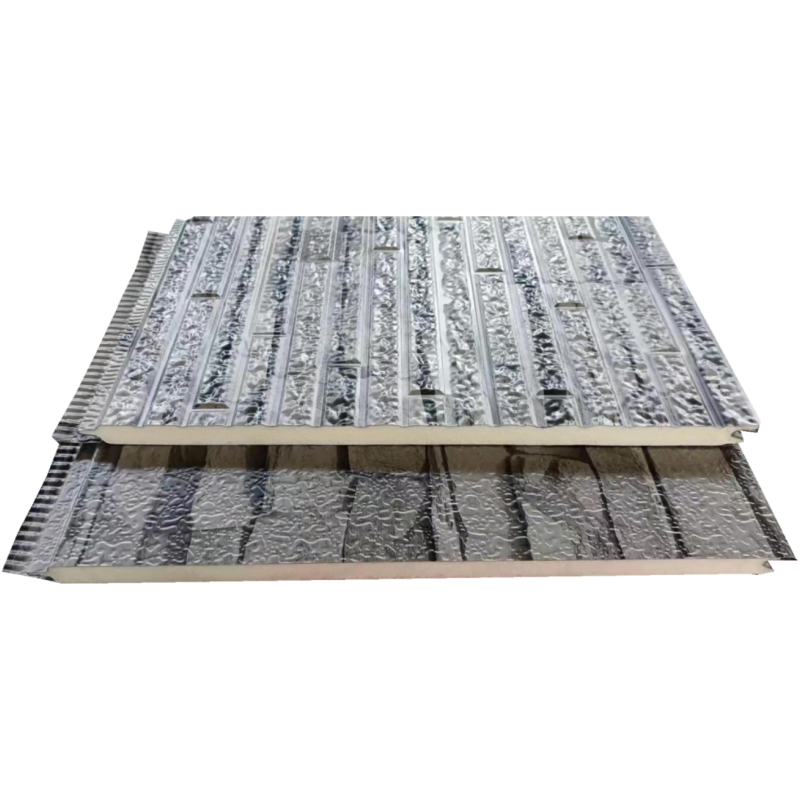

Functional Design and Core Technology: The structure consists of two durable metal facing sheets, typically pre-finished steel or aluminum, bonded to a central layer of rigid polyurethane foam. This PU insulation core is renowned for its exceptionally low thermal conductivity and high R-value per inch, making these insulated metal panels (IMPs) highly effective energy saving building materials. The sandwich panel construction creates a lightweight yet structurally sound element.

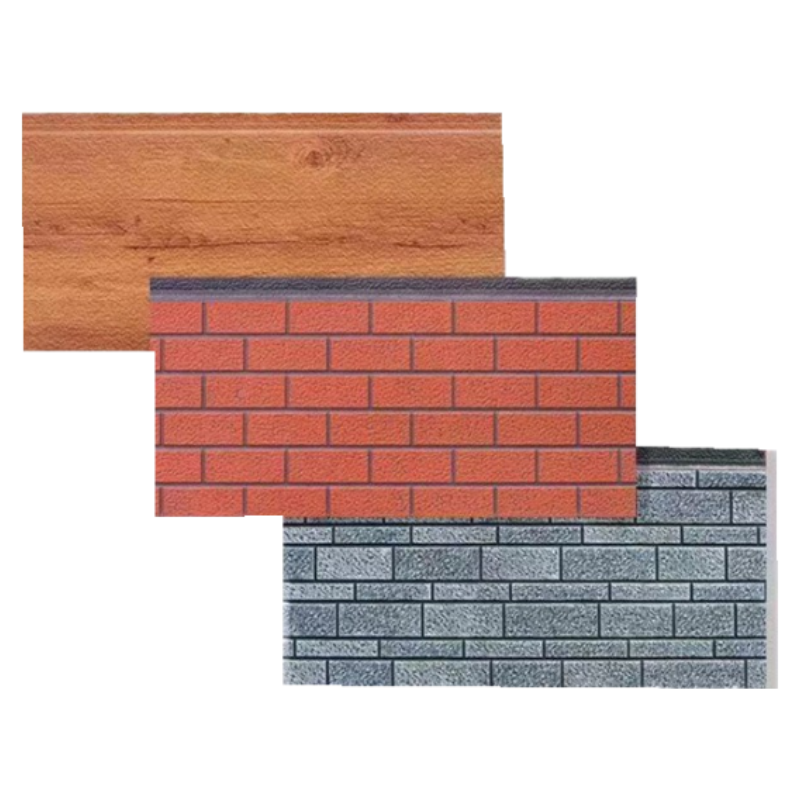

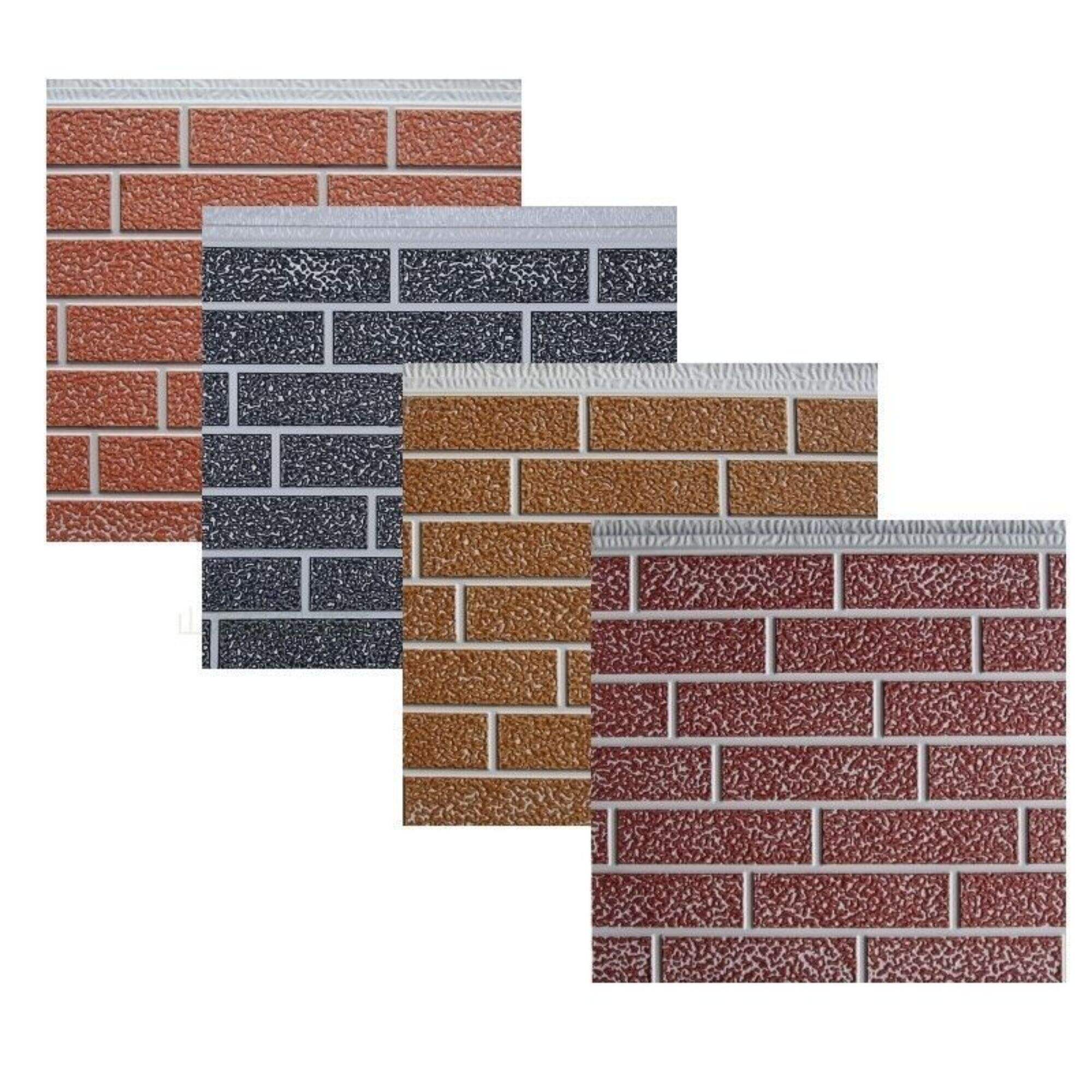

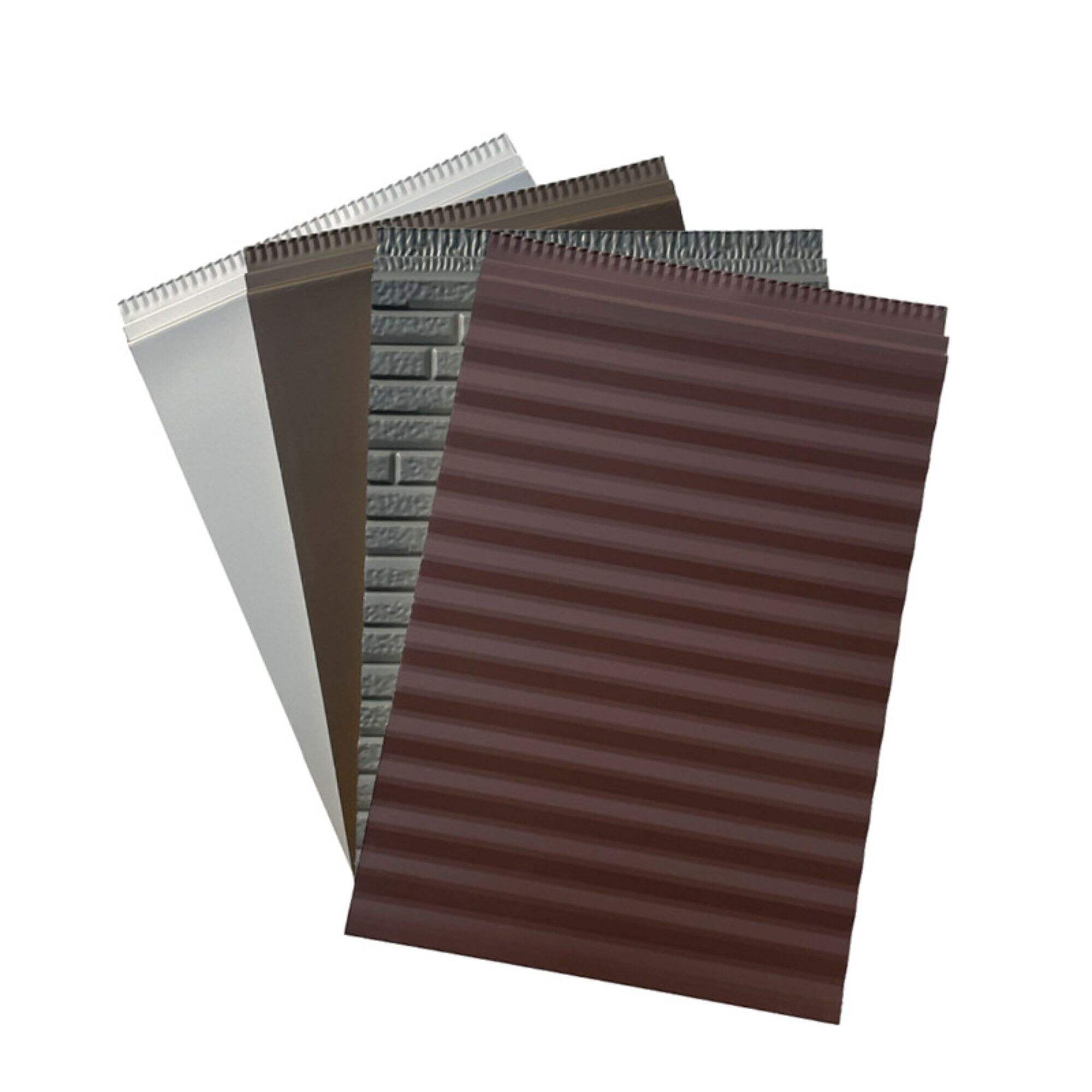

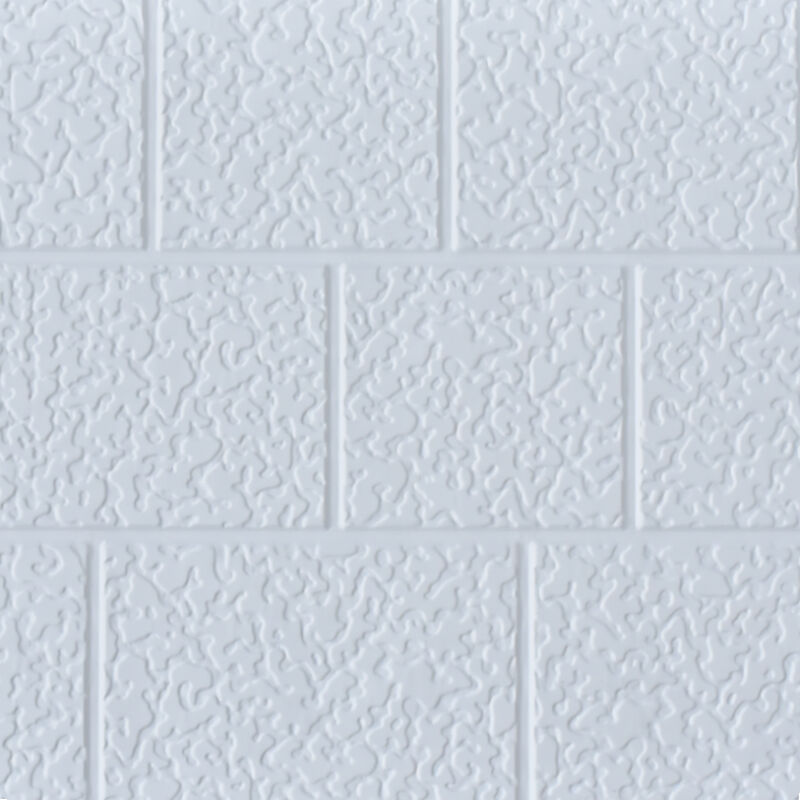

Aesthetic Versatility: The decorative metal surface of these carved facade panels offers extensive design flexibility. The embossed patterns range from subtle textures to intricate, three-dimensional designs, providing a distinctive architectural metal finish for exterior cladding systems and interior wall applications. This transforms functional building insulation panels into striking design elements.

Performance Characteristics: Beyond aesthetics, PU core metal carved boards deliver robust performance. The closed-cell foam core provides excellent thermal insulation properties, significantly reducing energy consumption for heating and cooling. These panels also contribute to acoustic insulation and possess inherent fire retardant properties (subject to specific fire ratings). Their inherent weather resistance and durability ensure low maintenance building facades suitable for diverse climates. The prefabricated panel system enables rapid installation, reducing construction timelines.

Product Parameter

| Surface Material: | Alu-Zn Galvanized Sheet |

| Core material: | Rigid Polyurethane Foam |

| Back Material: | Hard Moisture-proof Aluminum Foil Paper |

| Length: | Customized (2-5.8 meters is recommended for convenient transportation) |

| Standard thickness: | 14mm/16mm/20mm/25mm/30mm |

| Width: | 383mm |

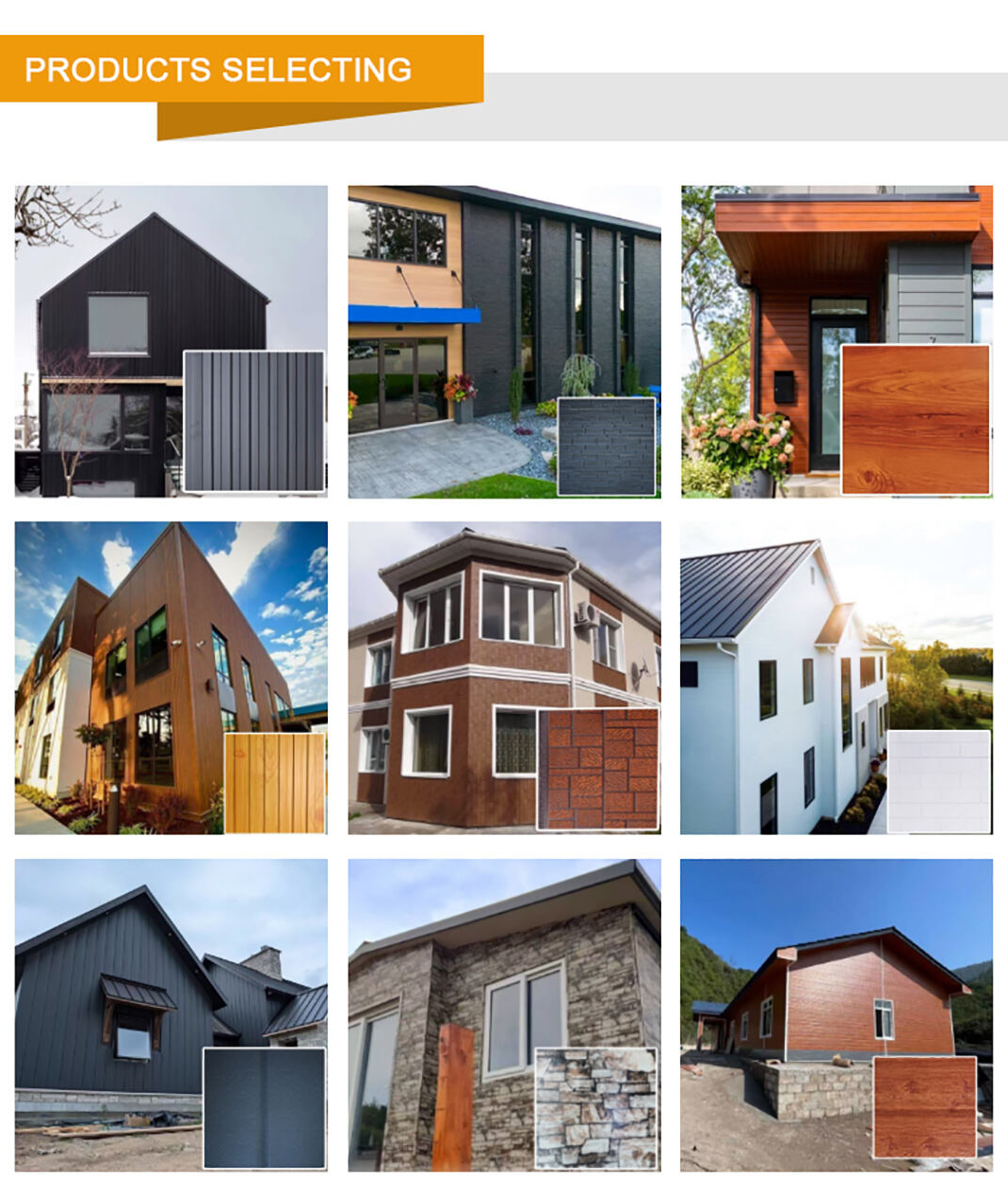

| Basic color: | Solid color, brick grain, stone grain, wood grain,Marbling or customized |

| Insulation performance: | Heat transfer coefficient≤0.018-0.024w/(m.k) |

| Core material density: | 42KG/m³ |

| Steel coil thickness: | 0.2-0.25mm |

| Zinc content: | 40-50g/m² |

| UV coating: | 50μm |

| Compressive strength(Kg/m2) | 0.2-0.7 |

| Recommended galvanized layer: | 150/m2 Hot aluminumzinc plating |

| Thermal resistance: | 0.44(m2-k)/W |

| Freeze-thaw resistance: | 0.18MPa |

| Wind load performance: | The test wind load value is 9 kPa. The sample is not damaged |

| Fire-proof level | Grade B |

| Application: | Hotel,Villa,Apartment,Building,Hospital,School,Mall,External,Internal,Roofing,Prefabricated House. |

| Installation method: | 1.Horizontal(horizontal)2.Vertical 3.Aluminium alloy fittings |

| Advantage | Fire resistant,Waterproof,Thermal Insulation,Soundproof,Earthquake proof,Eco-friendly,Flame Retardant,Easy Installation. |

| MOQ | 100 Square Meter |

| Payment Terms | T/T(30% as deposit and 70% be paid before loading)L/C(100% Irrevocable L/C at sight) or other payments can be negotiated. |

| Packaging Details | Carton or kraft paper, support customization8 PCS/CTN,10 PCS/CTN |

| Lead Time | 3-7days. Customized products 7-25 days. |

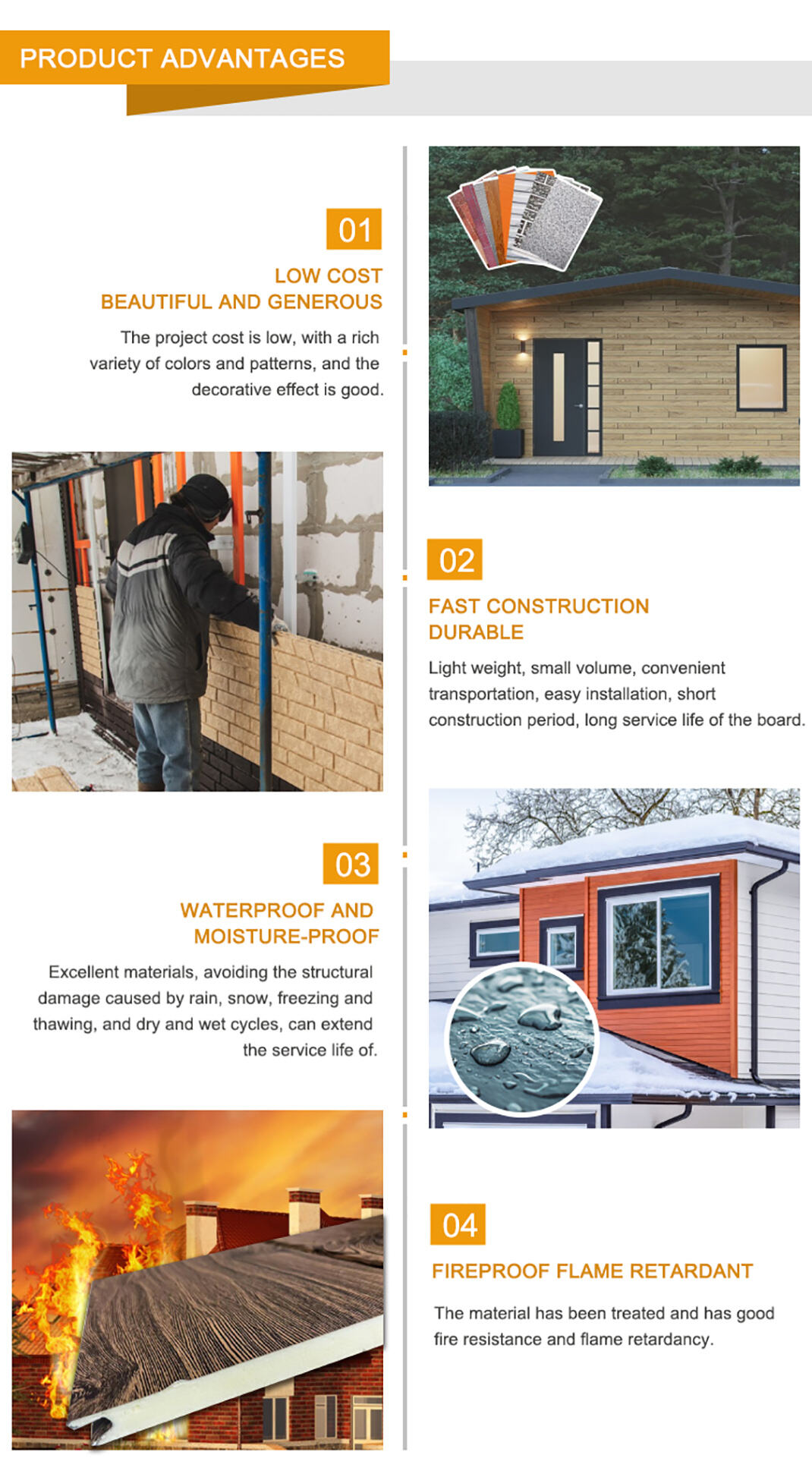

Product Advantages

Unmatched Insulation: Featuring a rigid PU foam core with an ultra-low thermal conductivity, our insulated wall panels and insulated roof panels deliver superior thermal insulation performance, significantly reducing energy costs for heating and cooling. Ideal for creating energy efficient building envelopes.

Lightweight Yet Strong: The unique sandwich panel construction combines the high insulation properties of PU with the durability of pre-painted galvanized steel or aluminum zinc coated steel facings. This results in a lightweight building panel offering excellent load-bearing capacity and structural integrity.

Exceptional Fire Safety: Our PU core sandwich panels utilize advanced fire-retardant formulations, achieving excellent fire resistance ratings (e.g., Class B / Class A) for enhanced building safety.

Durable & Weatherproof: The robust metal cladding panels provide outstanding resistance against corrosion, impact, UV radiation, and harsh weather conditions, ensuring long-lasting performance and minimal maintenance. Perfect for demanding architectural metal cladding.

Aesthetic Versatility: Available in a wide range of profiles (including smooth, embossed, and woodgrain patterns) and RAL color coated finishes, our metal decorative panels offer architects and builders unparalleled design flexibility for stunning building facades and interiors.

Fast & Efficient Installation: Designed as prefabricated building panels, they enable rapid, dry construction, reducing overall project timelines and labor costs significantly.

Application Scenarios

Our decorative Polyurethane Core Metal Panels are the perfect choice for:

1.Commercial Building Facades (Offices, Showrooms, Malls)

2.Industrial Building Cladding (Factories, Warehouses, Logistics Centers)

3.Cold Storage & Refrigerated Warehouses

4.Clean Rooms & Pharmaceutical Facilities

5.Agricultural Buildings

6.Retail Outlets & Supermarkets

7.Residential Accents & Modern Homes

8.Renovation & Retrofit Projects (Over existing facades)

9.Partition Walls & Interior Features

Commitment to Quality:

Our PU insulated Sandwich panels and insulated roof panels are manufactured under strict quality control, We offer custom fabrication to meet specific project dimensions and architectural visions.

Upgrade your next project with the ultimate combination of beauty, performance, and efficiency. Discover how our decorative polyurethane sandwich panels can transform your building envelope into a high-performing, aesthetically stunning asset. Request samples, technical data sheets, or a quote today to experience the difference premium metal cladding solutions make. Invest in energy-efficient construction with long-lasting, low-maintenance PU core panels – the smart choice for modern architectural metal panels.

FAQ

Q: How do I maintain and clean the panels?

A:Maintenance is very simple. Normally, occasional rinsing with water is sufficient to remove dust and dirt. For tougher stains, a mild detergent and soft cloth can be used. The high-hardness, anti-oxidation surface resists staining and is easy to clean.

Q: Can I get a free sample before placing a bulk order?

A:Yes, we provide free sample panels so you can verify the quality, color, and texture. You only need to pay the shipping cost.

Q: What is the lead time for production and shipping?

A:For standard colors/patterns, the lead time is typically 10-15 days after order confirmation. For custom designs, it may take 15-20 days. We will provide a precise schedule based on your order quantity and requirements.

Q: Are your panels fire-resistant?

A:Yes, our polyurethane core is self-extinguishing and meets relevant international fire safety standards (e.g., B1 grade). Specific test reports can be provided upon request.

Q: What is the R-value or thermal insulation performance?

A:The 16mm PU core offers excellent thermal insulation with a K-value of approximately 0.024 W/m·K, significantly improving energy efficiency for buildings.

Q: Do you provide installation guides or support?

A:Yes, we provide detailed PDF installation guides and video tutorials. Our technical team is also available for online support if you have specific questions during installation.

Q: What is the minimum order quantity (MOQ)?

A:The MOQ for the 16mm thick panels is 1,500㎡, which is optimized for a 20ft container. We can also accommodate larger orders, with a 40ft container holding approximately 3,500㎡.

Q: Can I mix different colors/patterns in one container?

A:Absolutely. You can mix different colors and patterns in a single container to meet your 1,500㎡ MOQ, allowing for greater design flexibility.

Q: What payment terms do you accept?

A:We commonly accept T/T (Telegraphic Transfer) and L/C (Letter of Credit). For established relationships, other terms can be discussed.

Q: What's the address of our company?

A: No. 98, Environmental Protection Science and Technology Industrial Park, Diaozhen Street, Zhangqiu District, Jinan City, Shandong Province。Welcome to visit our factory.

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

HY

HY