Perhaps the best thing about these products is just how versatile they are and at Foamex, we supply foam core composite panels to dozens of different industries... from construction all the way through to aerospace. Poplar plywood panels have incredible strength and durability yet are extremely light in weight, making them an excellent choice for specific projects. Throughout this journey, we shall explore further behindthe curtain of foam core composite panels and back to the process of how they even got created!

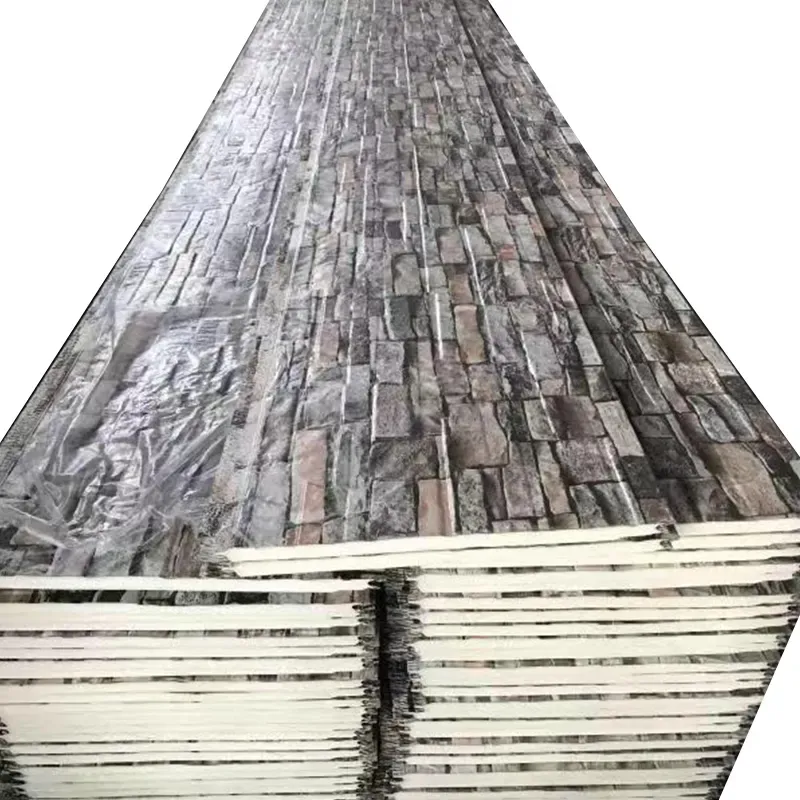

Transportation and installationExcept that the foam core material used to make composite panels will allow it fairly simply lighten up transpost problem. And much better than traditional building materials such as wood or metal. How cool is that and despite their zero weight, the panels are strong enough so you can park a presenhiale on top o them without any faultering. In the other part, their water resistance allows them to be used outdoors. Versatility of foam core composite panels is amazing and you can use them to build walls, roofs or even beautiful pieces of furniture items including art installations.

Yet the impact is no-less-revolutionary that foam core composite panels have had on construction. In this regard, they have made possible the design of taller + tensile-ier buildings that are as stable and durable (if not more) than their shorter squat cousins. On top of that, these are climate and energy-efficient siding options which eventually save the many heating and cooling processes carried on to maintain temperature inside. Their use of prefab and on-site assembly contribute to their efficiency/speed in construction processes-which makes them have a solid place as an industry game-changer.

Foam core composite panels are a highly versatile material that can also be used for many different applications including construction and manufacturing industries. From playing an essential role in construction of walls, roofs and floors to being carved into intense piece of furniture entrees or art installations even components for musical instruments these panels are imperative primacies happen with them. Moreover, since the aerospace and transportation industry are their major applications it further adds to how important they are in making strong but lightweight material for airplanes, spacecrafts from inside out starting with small airplane parts, car body part of vehicle or hull shell of a boat.

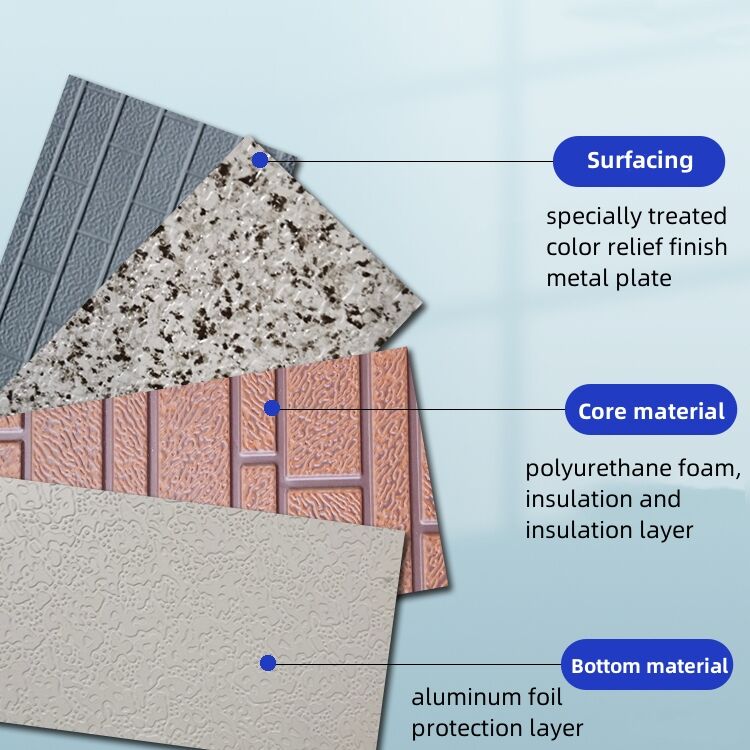

To understand this, you must add to the equation that foam core composite panels can perform as good or better than other materials. These panels feature a lightweight foam core sandwiched between two layers of tough plastic or metal and the materials used in such an arrangement tend to be polyurethane, fiberglass: aluminum, polystyrene etc. This construction enables the seamless integration of lightweight design and durability.

Step-by-Step Look at How Foam Core Composite Panels are manufactured in Australia

The complex operation of the production of foam core composite panels starts with creating foam core that is through a chemical reaction to make the low-density material expand and become hard. After this, a series of outer layers - usually consisting of resin sprayed or rolled on followed by fiberglass or aluminum, then another layer of resin - is painstakingly added. Curing The panels are left to cure in a oven for the set time needed With so, It will consolidate or harden the unsaturated polyester resin and give it its final form.

All of these applications have been made possible by the innovative foam core composite panels, making this a new age for construction and manufacturing with an ability to layer strength on cost effectiveness in countless ways. No matter if you are setting forth to construct a home, create marine vessels or even sculpt custom furniture type products you can count on foam core composite panels that will last and guarantee full performance.

Our company offers top-quality after-sales support. Our products can sent anywhere on the world in a timely time, at affordable price, with exemplary service and premium. We have friendly and knowledgeable team. The most well-known shipping foam core composite panels provide preferential freight.

Our products are customizable to include branding packaging, quantity, and trademarks in accordance the needs of our customers. The surface of our products may be entirely smooth or with a textured surface. The color, size and trademark can be customized according needs. We have an impressive capacity for supply, advanced foam core composite panels well as the most advanced equipment to meet the customer's requirements.

Our products are easy to put up and use less energy. They can also aid cutting expenses. Wall panels are light that is space-saving, earthquake-resistant, and resist cracks; they are also flame-retardant and waterproof. They are also moisture-proof, waterproof, and sound-proof, providing you a quiet and comfortable space. They are green, eco-friendly high-end, durable are widely foam core composite panels.

To protect the interests of our clients We always offer high-quality products reasonable prices. We treat every client with respect treat them like friends. Whatever their origins from, we do business with them and build relationships with them. Each year, we launch brand new designs for every category. Each foam core composite panels is made using the highest standards quality.

Copyright © Shandong Qigong Environmental Protection Technology Co., Ltd. All Rights Reserved Privacy Policy Blog