Here's what you need to know about using aluminum sandwich panels for your building exteriors

Architects and builders are looking for durable, strong materials that look great when it comes to selecting exterior cladding on a building. Naturally, from so may other choices prevailing around us in the market but here comes these most loved sandwich panel aluminium choice which is accepted to offer amazing and exceptionally adaptable applications.

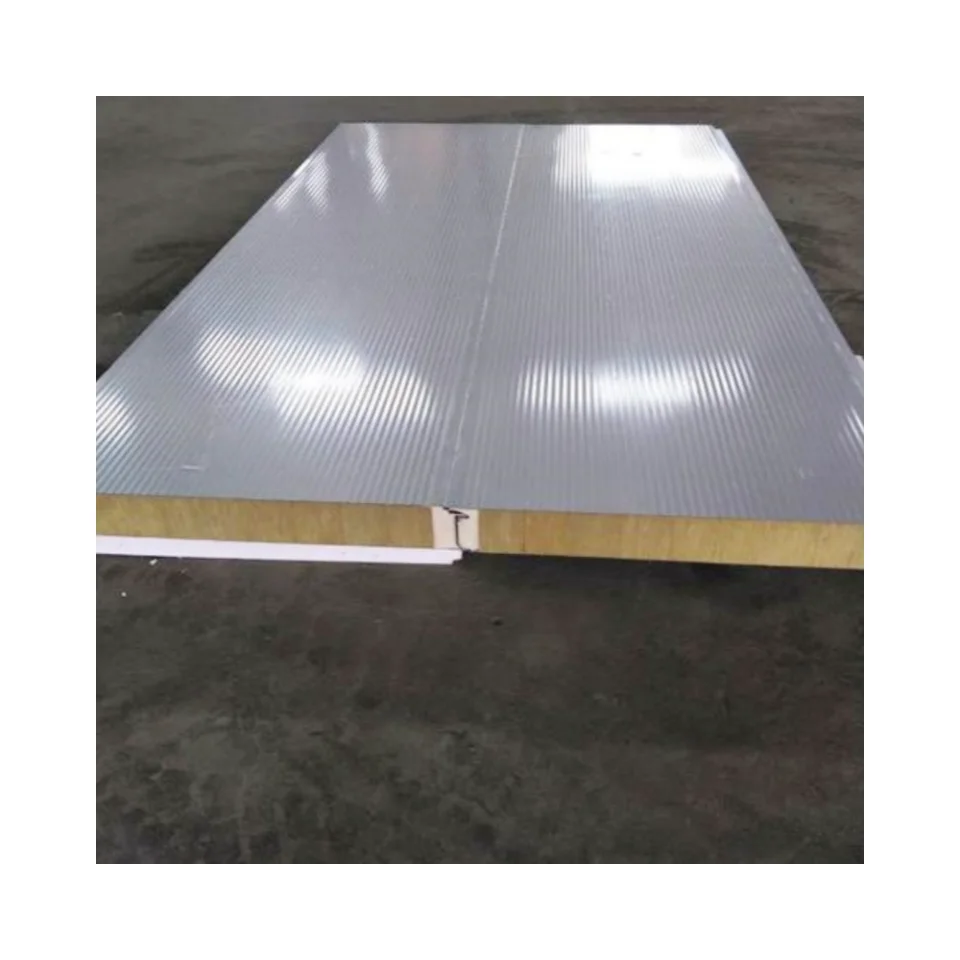

A sandwich panel is formed from an aluminum sheet (also known as facade or skin), bonded under pressure to a lightweight core made of some other material -- usually plastic such as polyethylene. The panel combines these two materials to give you a pie with the best slices from both worlds; strength of aluminum and everything extra that this core material has. The result is a panel which can be used in many ways to make the lighter, cheaper panels last for years.

The cost-benefit-factor is often a key determinant in choosing an exterior cladding material. Though aluminum sandwich panels may not be the cheapest choice originally, they serve a good return on your investment. The panels are extremely long lasting and low maintenance, so they can stand the test of time without degrading.

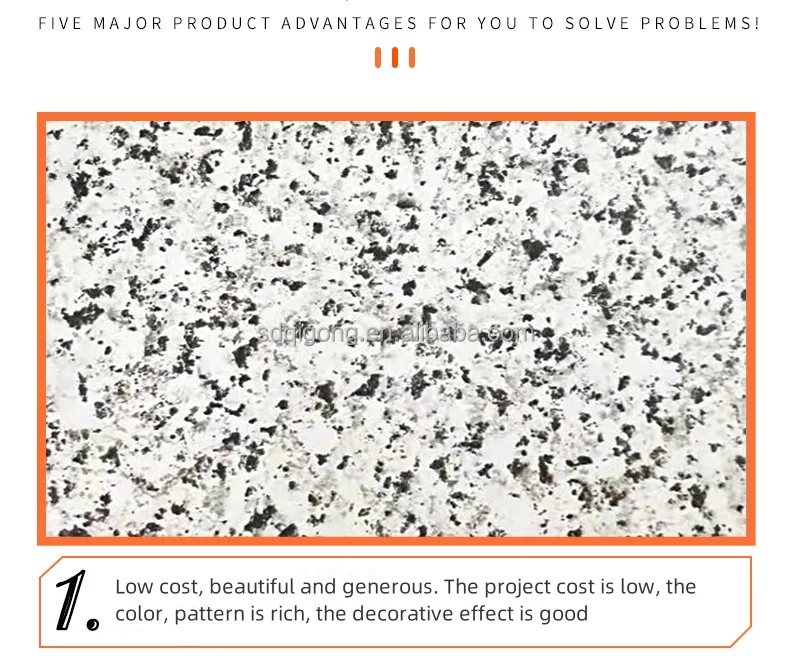

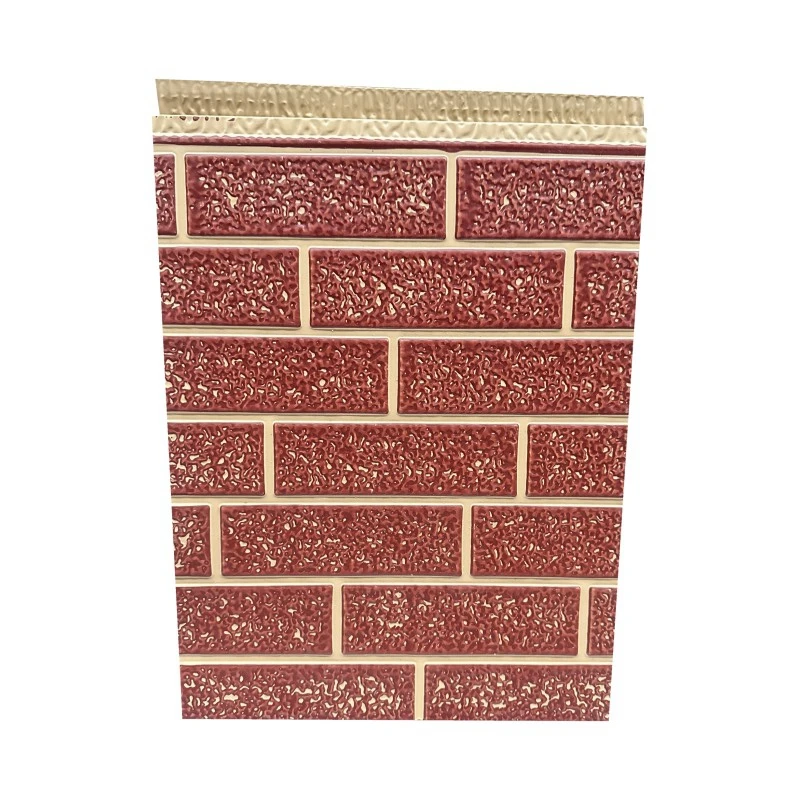

In addition, said aluminum sandwich panels also have high adaptability compared to other alternatives. These panels can be customized to accommodate for every individual project requirement, may that mean altering the size or even selecting color and finish. Installation of these roofs is also simple equating to lower project costs.

Aluminum sandwich panel Aluminum is light cheap and everywhere it makes sense for using as an insulating material -- hence here uses of the word-- aluminum plastic composite to satisfy your needs. Though these panels are frequently found in the industrial constructions like skyscrapers, airports, and hospitals they also play a great role for residential ventures including villas/flats.

Aluminum sandwich panels are best known for their excellent weather resistance. Like at Romina, there will be a mix between traditional construction and the Ferrocement panels, making them suitable for use in prefabricated or rapid deployment scenarios. The magic comes with their durability combined with mycelium properties - extreme temperatures are no problem; Frostexpanels can handle snowfall - rainproofing after 500 years of continuous soaking is still on point), winds from hurricane-force to tornadoes have little impact as these hydrophobic core material gains zero moisture inside water-resistance level still retains itself even though fibers absorbed humidity creates thight =,, fire causes obvious heating due releasing fumes prevent internal concentration flammable gases).

Strong and Durable: The unique composition of aluminium sandwich panels endows them with strength and durability. These panels are made up of two aluminum sheets bonded to a thermoplastic or tough fire-rated mineral core material and offer an attractive in addition to the highly functional surface thereby providing options that improve any building design.

The construction achieves to create lightweight panels, which are fast and easy to handle, reducing installation time/costs significantly but at the same incombines them with an incredible structural integrity that can be thrown off a 10-story-building without taking damage (without me actually telling you so; some things may just not even occur).

In addition, thermal insulation also comes from within the core material: This helps save costs on energy and ensures a comfortable living environment. These qualities combined make aluminum sandwich panels a dependable, durable and effective choice for external siding.

Aluminum sandwich panels are simple to install and can be installed by any licensed professional. By cutting, drilling and shaping this is easy to achieve with these panels that can be readily tailored for whichever use the project calls requires.

This is important to ensure that the panels have a lifespan and work as efficiently as they should. A mixture of mild detergent and water is enough to scrub clean regularly, without the need for harsh chemicals that can damage your panel's surfaces.

Inspection for signs of wear or damage should always be regular Being able to catch and remedy any problems that may arise immediately is key, as you do not want the panels failing because they have not been taken care of.

Our products are customizable include branding Aluminium sandwich panel, quantity, and trademarks according to the requirements the customer. The surface of our products is completely smooth or textured. The size, color and logo of our products are tailored to meet your needs. Our company able to supply high capacity, advanced technology skills and modern equipment to meet customer requirements.

We are always able to guarantee high quality and competitive pricing to safeguard the interests of customers. We treat each customer like would our family and we treat them as such. We deal with everyone, no matter where they come from. Each year, we launch new designs each category. All products Aluminium sandwich panel made and 100% quality-tested.

We offer a top-quality service after sale. Our products can shipped anywhere on the world in a timely manner, at a reasonable price, with excellent Aluminium sandwich panel top-quality. However, we have very professional and pleasant staff. well-known shipping companies provide most favorable freight.

Our products are easy to put up and use less energy. They can also aid cutting expenses. Wall panels are light that is space-saving, earthquake-resistant, and resist cracks; they are also flame-retardant and waterproof. They are also moisture-proof, waterproof, and sound-proof, providing you a quiet and comfortable space. They are green, eco-friendly high-end, durable are widely Aluminium sandwich panel.

Copyright © Shandong Qigong Environmental Protection Technology Co., Ltd. All Rights Reserved Privacy Policy Blog