16mm Metal Siding - Insulated Polyurethane Wall Panel for Chilean Homes & Buildings

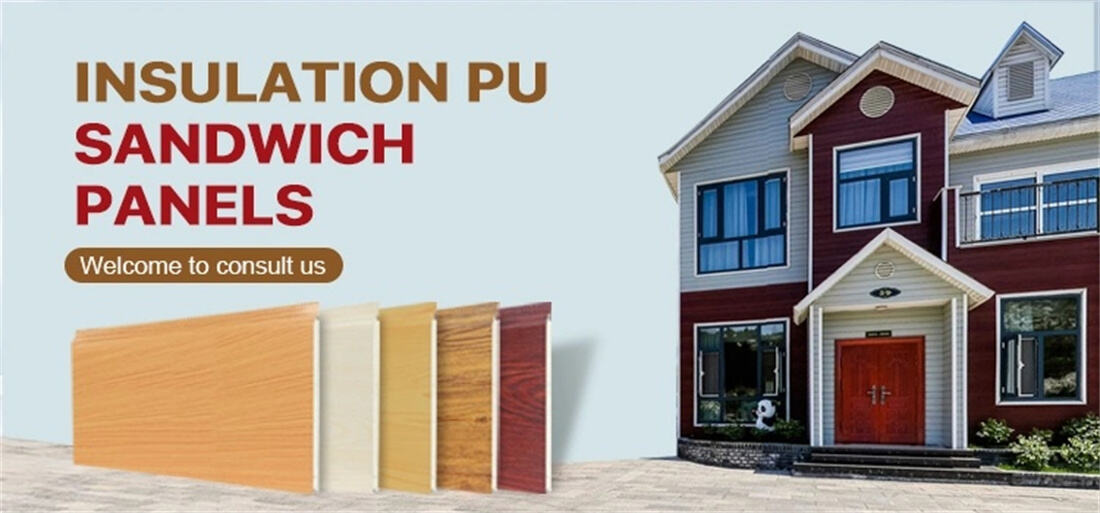

Elevate your architectural vision with SDQIGONG Polyurethane Sandwich Panels. We masterfully blend the warm, timeless appeal of authentic wood grain with the superior strength and innovation of modern metal cladding, creating a facade solution that is as intelligent as it is stunning.SDQIGONG panels offer remarkable durability, fire resistance, and weatherproofing, ensuring your building's elegance stands the test of time.

MOQ:1,500㎡ (suitable for 20ft container)

- Overview

- Product Description

- Product Parameter

- Product Advantages

- Application Scenarios

- FAQ

- Inquiry

- Related Products

Product Description

Polyurethane Core Metal Carved Sandwich Panels: Combining Aesthetics with Performance

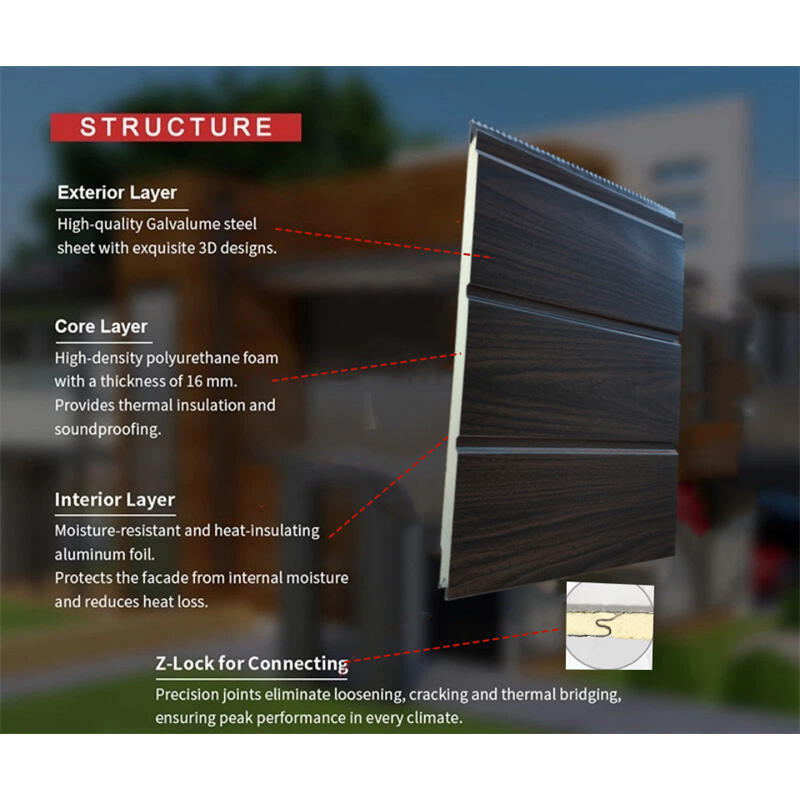

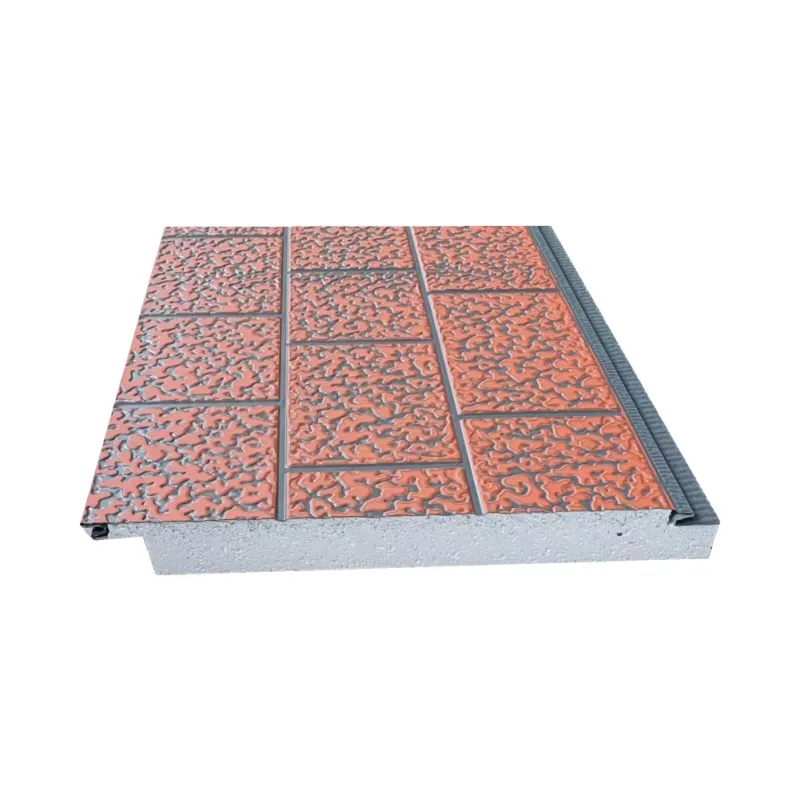

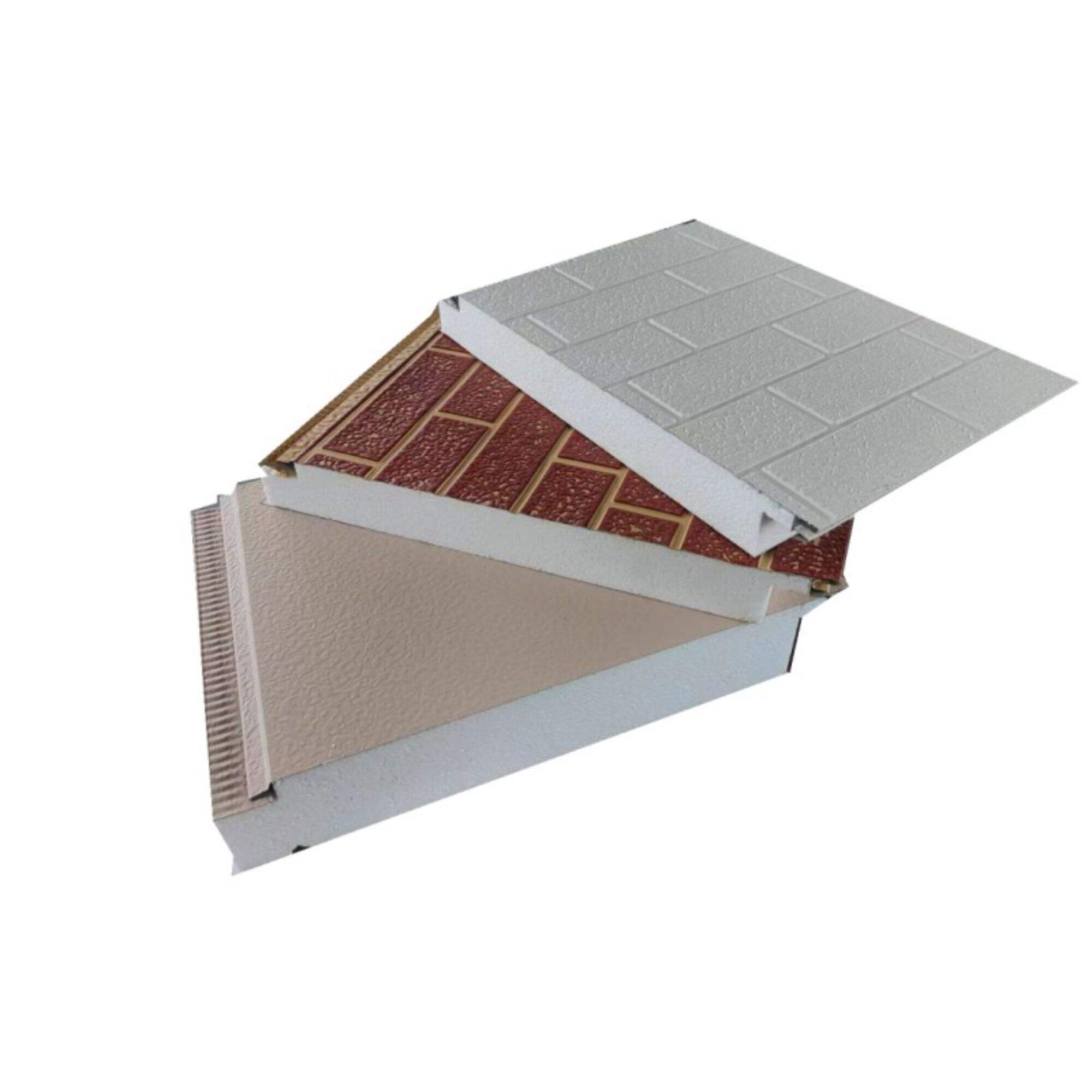

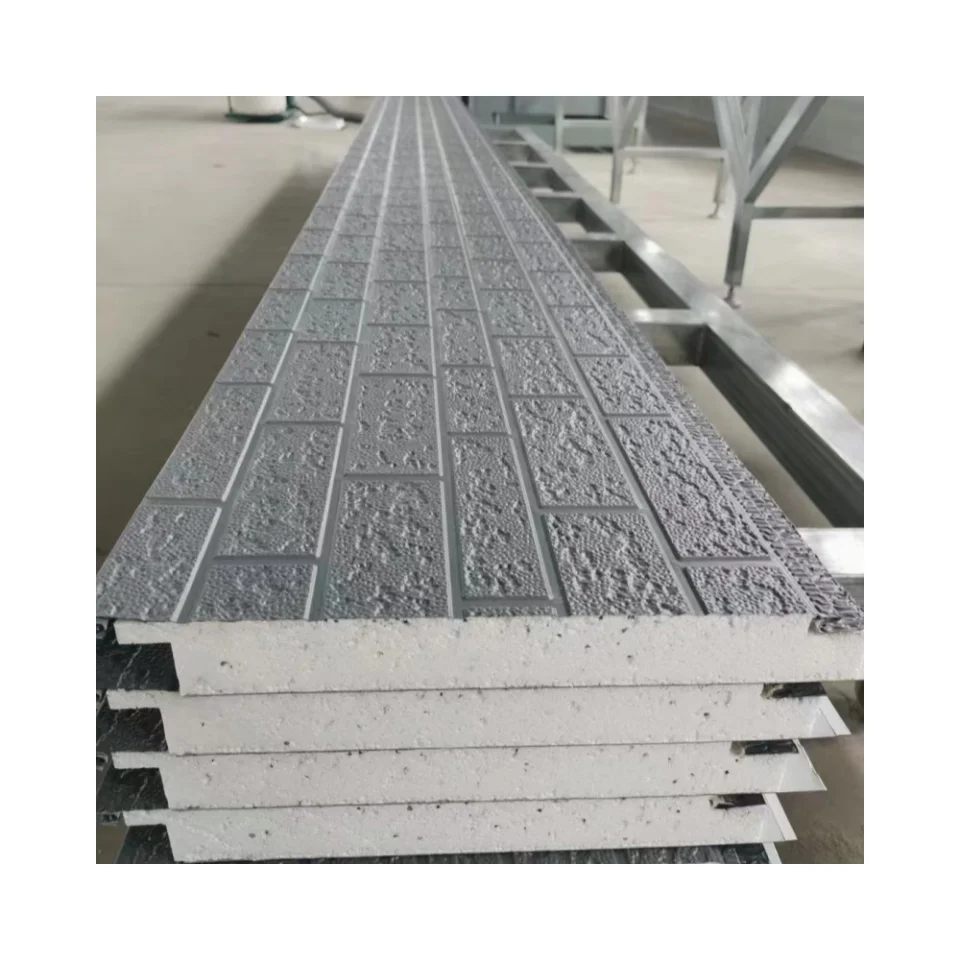

Metal carved sandwich panels with a rigid polyurethane (PU) insulation core represent a significant advancement in modern building envelope solutions. These composite panels integrate the visual appeal of intricately embossed metal facings – the defining feature of metal carved boards – with the exceptional thermal efficiency of PU core sandwich panels.

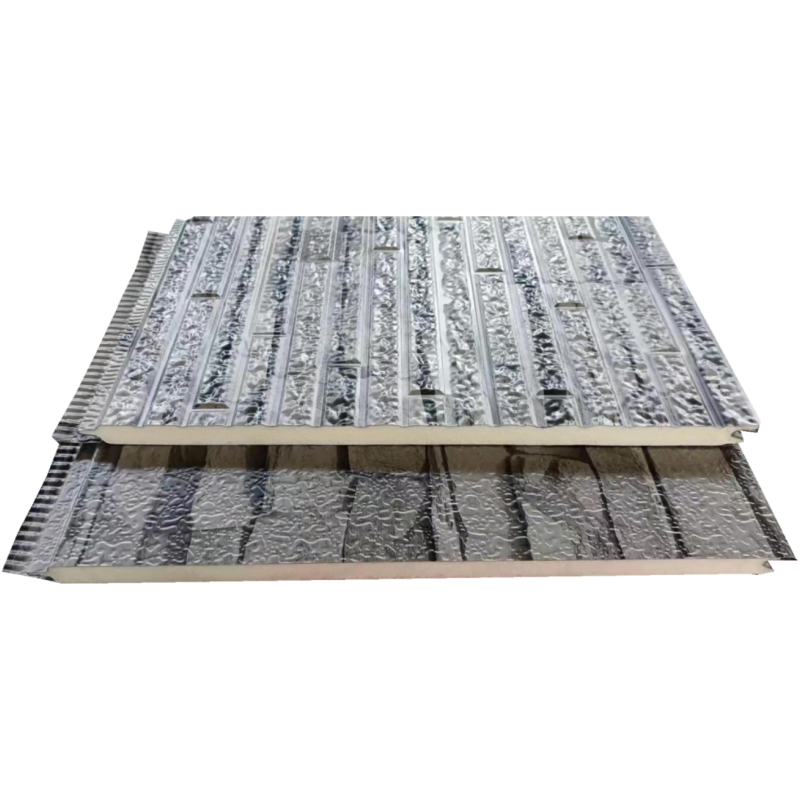

Functional Design and Core Technology: The structure consists of two durable metal facing sheets, typically pre-finished steel or aluminum, bonded to a central layer of rigid polyurethane foam. This PU insulation core is renowned for its exceptionally low thermal conductivity and high R-value per inch, making these insulated metal panels (IMPs) highly effective energy saving building materials. The sandwich panel construction creates a lightweight yet structurally sound element.

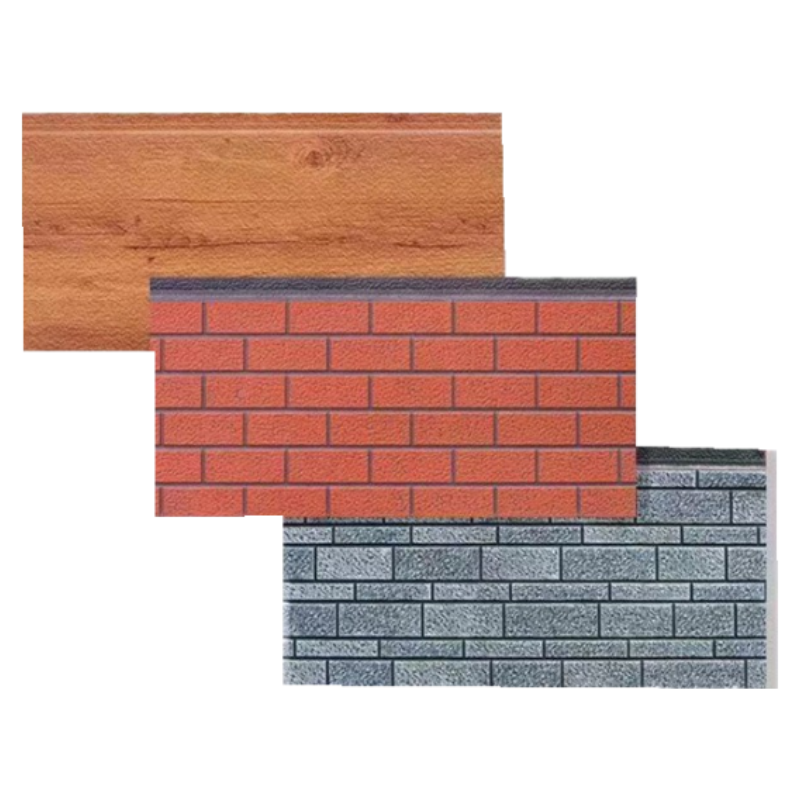

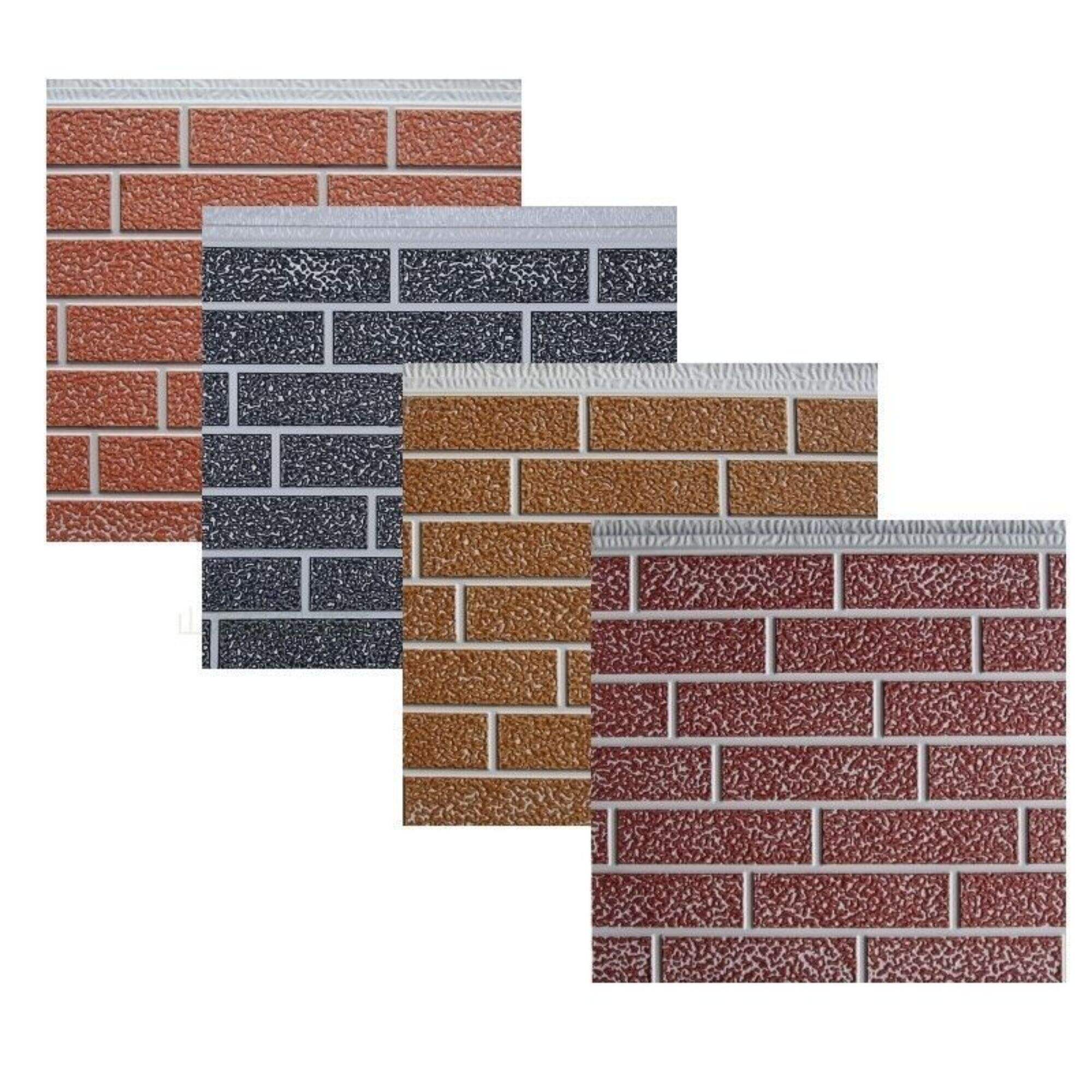

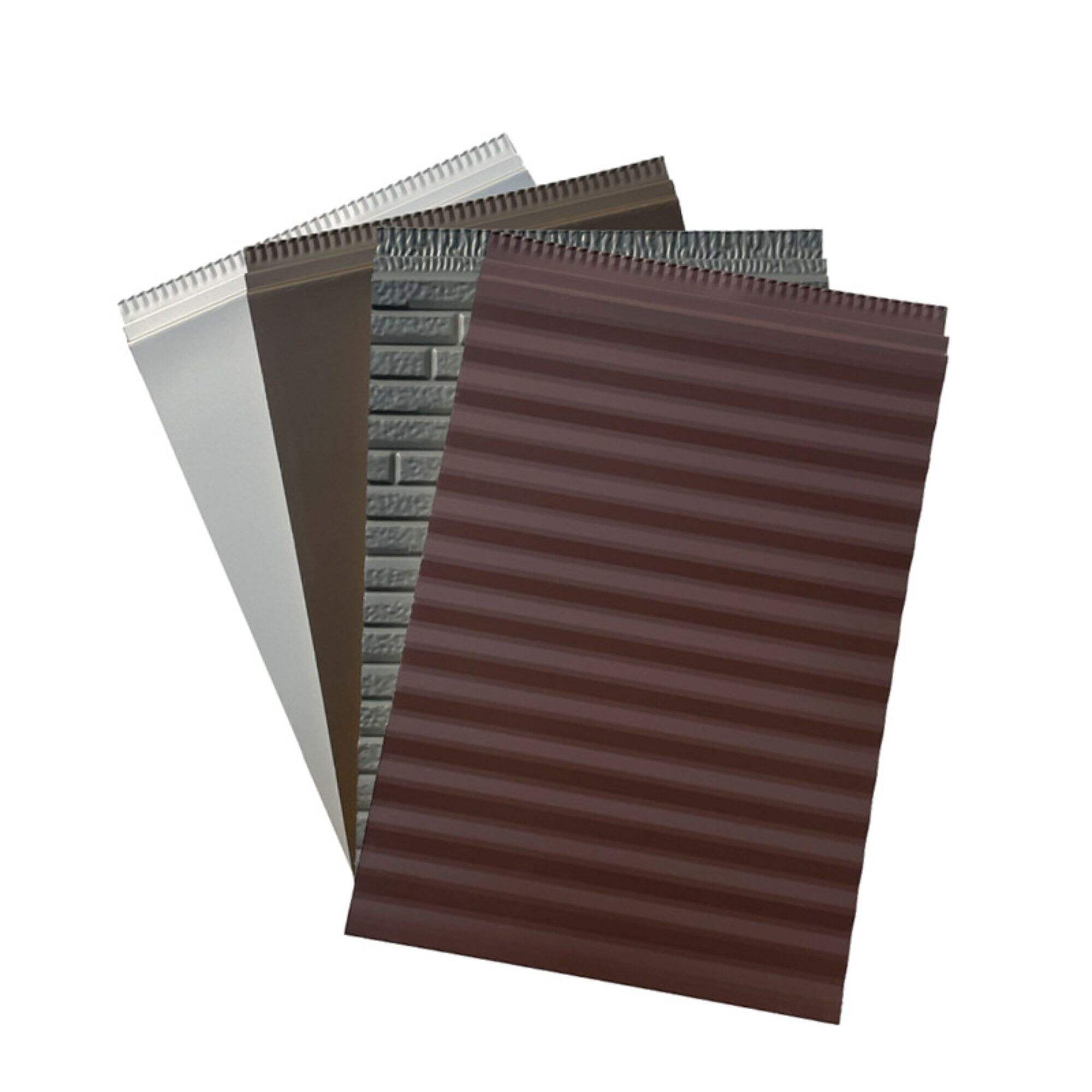

Aesthetic Versatility: The decorative metal surface of these carved facade panels offers extensive design flexibility. The embossed patterns range from subtle textures to intricate, three-dimensional designs, providing a distinctive architectural metal finish for exterior cladding systems and interior wall applications. This transforms functional building insulation panels into striking design elements.

Performance Characteristics: Beyond aesthetics, PU core metal carved boards deliver robust performance. The closed-cell foam core provides excellent thermal insulation properties, significantly reducing energy consumption for heating and cooling. These panels also contribute to acoustic insulation and possess inherent fire retardant properties (subject to specific fire ratings). Their inherent weather resistance and durability ensure low maintenance building facades suitable for diverse climates. The prefabricated panel system enables rapid installation, reducing construction timelines.

Product Parameter

| Surface Material: | Alu-Zn Galvanized Sheet |

| Core material: | Rigid Polyurethane Foam |

| Back Material: | Hard Moisture-proof Aluminum Foil Paper |

| Length: | Customized (2-5.8 meters is recommended for convenient transportation) |

| Standard thickness: | 14mm/16mm/20mm/25mm/30mm |

| Width: | 383mm |

| Basic color: | Solid color, brick grain, stone grain, wood grain,Marbling or customized |

| Insulation performance: | Heat transfer coefficient≤0.018-0.024w/(m.k) |

| Core material density: | 42KG/m³ |

| Steel coil thickness: | 0.2-0.25mm |

| Zinc content: | 40-50g/m² |

| UV coating: | 50μm |

| Compressive strength(Kg/m2) | 0.2-0.7 |

| Recommended galvanized layer: | 150/m2 Hot aluminumzinc plating |

| Thermal resistance: | 0.44(m2-k)/W |

| Freeze-thaw resistance: | 0.18MPa |

| Wind load performance: | The test wind load value is 9 kPa. The sample is not damaged |

| Fire-proof level | Grade B |

| Application: | Hotel,Villa,Apartment,Building,Hospital,School,Mall,External,Internal,Roofing,Prefabricated House. |

| Installation method: | 1.Horizontal(horizontal)2.Vertical 3.Aluminium alloy fittings |

| Advantage | Fire resistant,Waterproof,Thermal Insulation,Soundproof,Earthquake proof,Eco-friendly,Flame Retardant,Easy Installation. |

| MOQ | 100 Square Meter |

| Payment Terms | T/T(30% as deposit and 70% be paid before loading)L/C(100% Irrevocable L/C at sight) or other payments can be negotiated. |

| Packaging Details | Carton or kraft paper, support customization8 PCS/CTN,10 PCS/CTN |

| Lead Time | 3-7days. Customized products 7-25 days. |

Product Advantages

1.Superior Thermal InsulationWith a thermal conductivity of ≤0.024W/(m·K), our 16mm polyurethane panels excel in Chile’s diverse climates—from the -10℃ cold of the south to the 35℃ heat of the north, keeping interiors comfortable year-round.

2.Strong Wind & Weather ResistanceBoasting wind pressure resistance of ≥1.5kPa, these panels stand firm against coastal winds (e.g., Valparaíso) and harsh elements, ensuring long-term structural stability.

3.20+ Year DurabilityUV-stable and corrosion-resistant, they eliminate frequent repainting or replacements. A cost-saving choice for low-maintenance buildings.

4.Lightweight & Fast to InstallWeighing just 8-10kg/㎡, they reduce structural load. Cut installation time by 30% with simple, tool-friendly fitting—ideal for tight project deadlines.guaranteeing safety and regulatory approval for all construction projects in Chile.

Application Scenarios

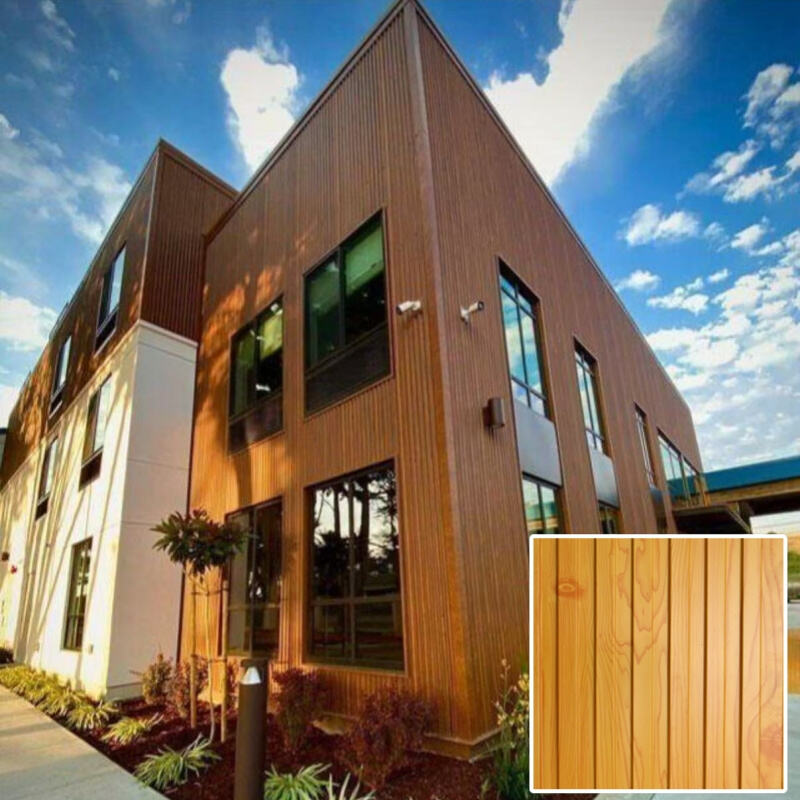

Wood Grain Pattern - Pattern Description

Our wood grain panels replicate the irregular textures and subtle color variations of natural solid wood, from light oak to deep walnut tones. The surface features a matte finish that avoids glare under Chile’s intense sunlight, while the embossed texture mimics the tactile feel of real wood grains—combining the warmth of natural timber with the durability of metal.

Application Scenarios & Cases

| Application Scenario | English Copy | Image Matching Suggestions |

| Chilean Rural Villa Exteriors | Ideal for rural villas in regions like Los Ríos and Araucanía. The warm wood tones blend harmoniously with surrounding forests and farmlands, creating a cozy rustic vibe. A recent renovation project of 20 rural villas in southern Chile used our light oak - grain panels. They withstood the local - 10℃ winter cold and high humidity, maintaining a flawless appearance without warping or fading for 3 years. | Exterior full - shot of a Chilean rural villa with light oak - grain panels; close - up of the panel texture against the villa's tiled roof and surrounding greenery. |

| Small Town Mall Storefronts | Perfect for boutique stores and café storefronts in small Chilean towns such as Pucón. The deep walnut wood grain adds a high - end and inviting touch, attracting passers - by. A boutique clothing store in downtown Pucón adopted our walnut - grain panels for its facade. It increased the store's foot traffic by 25% compared to neighboring shops with plain metal facades, thanks to the warm and elegant visual appeal. | Street - view shot of the boutique storefront with walnut - grain panels; close - up of the panel matching the store's glass doors and wooden display windows. |

| Mountain Chalet Renovations | Suited for mountain chalets in the Andes near Santiago. The wood grain echoes the alpine forest scenery, and the panel's thermal insulation keeps the chalet warm during snowy winters. A chalet resort in Valle Nevado used our wood - grain panels for 15 chalet exteriors, reducing heating costs by 30% annually while blending naturally with the snow - covered mountain landscape. | Aerial shot of the chalet resort with wood - grain panels surrounded by snow; interior - exterior transition shot showing the panel's coordination with the chalet's wooden interiors. |

Application Scenario

English Copy

Image Matching Suggestions

Chilean Rural Villa Exteriors

Exterior full - shot of a Chilean rural villa with light oak - grain panels; close - up of the panel texture against the villa's tiled roof and surrounding greenery.

Small Town Mall Storefronts

Perfect for boutique stores and cafe storefronts in small Chilean towns such as Pucon. The deep walnut wood grain adds a high - end and inviting touch, Youdaoplaceholder0 passers-by-a boutique clothing store in downtown Pucon adopted our walk-grain panels for its facade. It increased the store's foot traffic by 25% compared to neighboring shops with plain metal facades, thanks to the warm and elegant visual appeal.

Street - view shot of the boutique storefront with walnut - grain panels; close - up of the panel matching the store's glass doors and wooden display windows.

Mountain Chalet Renovations

Suited for mountain chalets in the Andes near Santiago. The wood grain echoes the alpine forest scenery, and the panel's thermal insulation keeps the chalet warm during snowy winters. A chalet resort in Valle Nevado used our wood - grain panels for 15 chalet exteriors, reducing heating costs by 30% annually while blending naturally with the snow - covered mountain landscape.

Aerial shot of the chalet resort with wood - grain panels surrounded by snow; interior - exterior transition shot showing the panel's coordination with the chalet's wooden interiors.

FAQ

Q: How do I maintain and clean the panels?

A:Maintenance is very simple. Normally, occasional rinsing with water is sufficient to remove dust and dirt. For tougher stains, a mild detergent and soft cloth can be used. The high-hardness, anti-oxidation surface resists staining and is easy to clean.

Q: Is the 16mm polyurethane sandwich panel suitable for Chile’s southern cold climate?

A: Yes, it is. With a thermal conductivity of ≤0.024W/(m·K), the 16mm thickness effectively retains heat, meeting the insulation needs of regions with temperatures as low as -10℃. It has been tested and applied in southern Chilean areas, maintaining stable performance even in harsh winters.

Q: Do the wood grain, grooved, and Great Wall panel patterns require special maintenance?

A: No special maintenance is needed. All panels feature a UV-resistant and corrosion-proof coating. Simply clean the surface with water and a soft brush occasionally to remove dust or debris—no repainting or refinishing is required for 20+ years.

Q: Can I get a free sample before placing a bulk order?

A:Yes, we provide free sample panels so you can verify the quality, color, and texture. You only need to pay the shipping cost.

Q: What is the lead time for production and shipping?

A:For standard colors/patterns, the lead time is typically 10-15 days after order confirmation. For custom designs, it may take 15-20 days. We will provide a precise schedule based on your order quantity and requirements.

Q: Are your panels fire-resistant?

A:Yes, our polyurethane core is self-extinguishing and meets relevant international fire safety standards (e.g., B1 grade). Specific test reports can be provided upon request.

Q: Do you provide installation guides or support?

A:Yes, we provide detailed PDF installation guides and video tutorials. Our technical team is also available for online support if you have specific questions during installation.

Q: What is the minimum order quantity (MOQ)?

A:The MOQ for the 16mm thick panels is 1,500㎡, which is optimized for a 20ft container. We can also accommodate larger orders, with a 40ft container holding approximately 3,500㎡.

Q: Can I mix different colors/patterns in one container?

A:Absolutely. You can mix different colors and patterns in a single container to meet your 1,500㎡ MOQ, allowing for greater design flexibility.

Q: What payment terms do you accept?

A:We commonly accept T/T (Telegraphic Transfer) and L/C (Letter of Credit). For established relationships, other terms can be discussed.

Q: What's the address of our company?

A: No. 98, Environmental Protection Science and Technology Industrial Park, Diaozhen Street, Zhangqiu District, Jinan City, Shandong Province。Welcome to visit our factory。

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

HY

HY