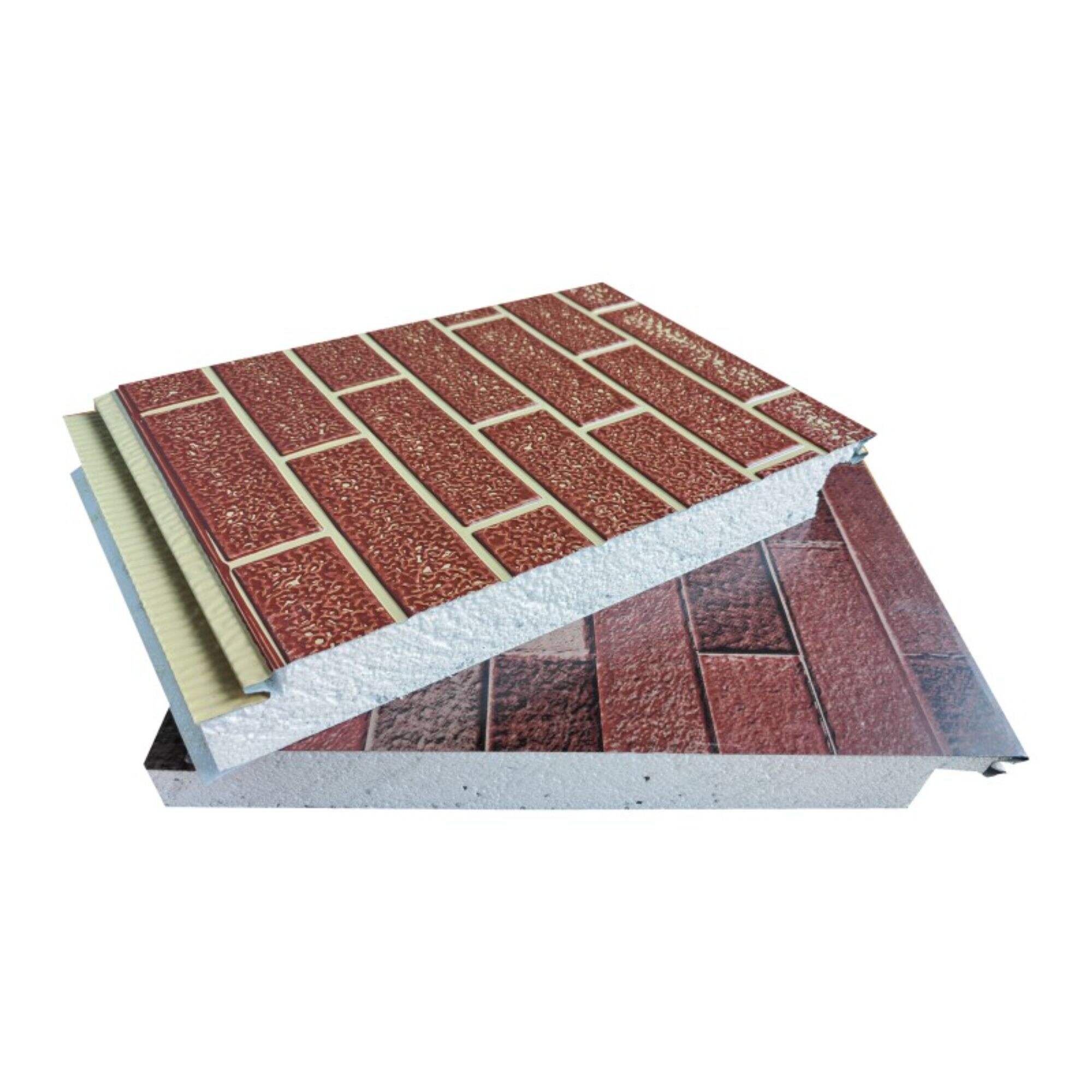

When the foam-core sandwich is being used, this material gains strength and becomes lightweight.

Like riding in boats and looking at the sea? If you have, then it is possible that you stumbled upon a term called foam sandwich! Sounds kind of like a tasty treat maybe but it is honestly one of the most interesting ways to build strong and lightweight items. Thing is, we can talk all day about the science behind foam sandwich and why it works well for certain applications.

What, then is a foam sandwich? A composite material that consists of a layer or insulation sandwiched between two facings, like wood or fiberglass. They are filled with core foam, the same ultra strong-super light foam used in high perfomance surfboards. And when used in with the other layers it makes for a surprisingly tough, yet lightweight material!

Foam sandwich is remarkable for the manner in which it can be created. Fist, a foam will be used. This is then sandwiched between two layers of the other material ie fibreglass. Special adhesive or even dense compression tools are used to bond everything together. Think of it as putting together a sandwich, but with foam!

Having just learned how foam sandwich is made - I bet this begs the question for you of why exactly its use offers such fantastic advantages! One of its best advantages is that it provides maximum strength while being extremely lightweight. It is a critical characteristic for applications like boats or airplanes where the material must be strong enough to bear weight but also needs to remain lightweight so as not counteract momentum. Denser materials are generally slower and less maneuverable than lighter weight options, therefore the use of foam sandwich can improve both speed as well as efficiency in boats or planes.

Another benefit is that they are tough, as with foam sandwich. Its layer of foam makes it great for shock absorption. Therefore, foam a sandwich crafted objects are more resilient to breaking or knocking damage from being struck.

No wonder foam sandwich is so versatile, Used everywhere from the construction of boat hulls, to airplane wings and furniture! Due to its rigidity and abrasion resistance, it is best for items that somewhat last longer even after extensive use.

Styrofoam sandwichA form of core material used in hulls, decks and other structures on boats is composed of a glass-fiber reinforced empty cell foam that has been cored with either plain (non-metalized) tinfoil or sheet steel. Foam sandwich boats are also the perfect choice because they will be required to float and get traffic on water, something which needs their weightiness along with being a durable material. In fact there are even marine grade foams built for the exact purpose!

The boats can be lighter, faster, more efficient and have less to no problem with comfort by using foam sandwich in them. It also helps to strengthen their ability to traverse the choppy waters, as this memory foam adds impact absorption effects for a softer sail.

Wait a minute, lets take closer look at the strength to weight of foam sandwich.

The best thing about foam sandwich is, it has an excellent Strength-to-weight ratio. " Weight for weight, it is stronger than any other material known to Man. A higher number means a robust, lightweight material.

Lightweight foam core, and hence a high strength-to-weight ratio more indicative of its hardiness than lightness. This makes it very useful for items like boats and airplanes which need to be strong enough to support great weight yet light enough not the weigh them down.

In order to enhance the performance of foam sandwich, some thought has to be put towards how we go about doing that. First, you have to choose which type of foam will best meet your needs. Different foam types have various levels of density and strength, so it is important to choose a material that best fits the task at hand.

Also, it is important to make sure that the foam really sits well in between all these materials. Correct alignment prevents inefficient shock absorption and distribution of support.

Finally, of course secure cohesion within the layers. When that layer separation starts occurring, the composite sandwich can lose some of its foam potential. This illustrates the importance of having custom-designed adhesives or equipment to maintain structural integrity.

So, the principle behind foam sandwich seems simple; but it must be executed with great forethought and materials technologies to join high-strength and low-density tissue together. Have you ever been on a boat or flying through the sky on an airplane - well, if so, then there is very high likelihood that foam sandwich was all around!

We provide high-end service after the sale. Our products able to be delivered to any part of the foam sandwich in a speedy way, and at fair price, with exemplary quality and service. Our company has a warm and professional team. Some of the most well-known shipping companies offer preferred freight.

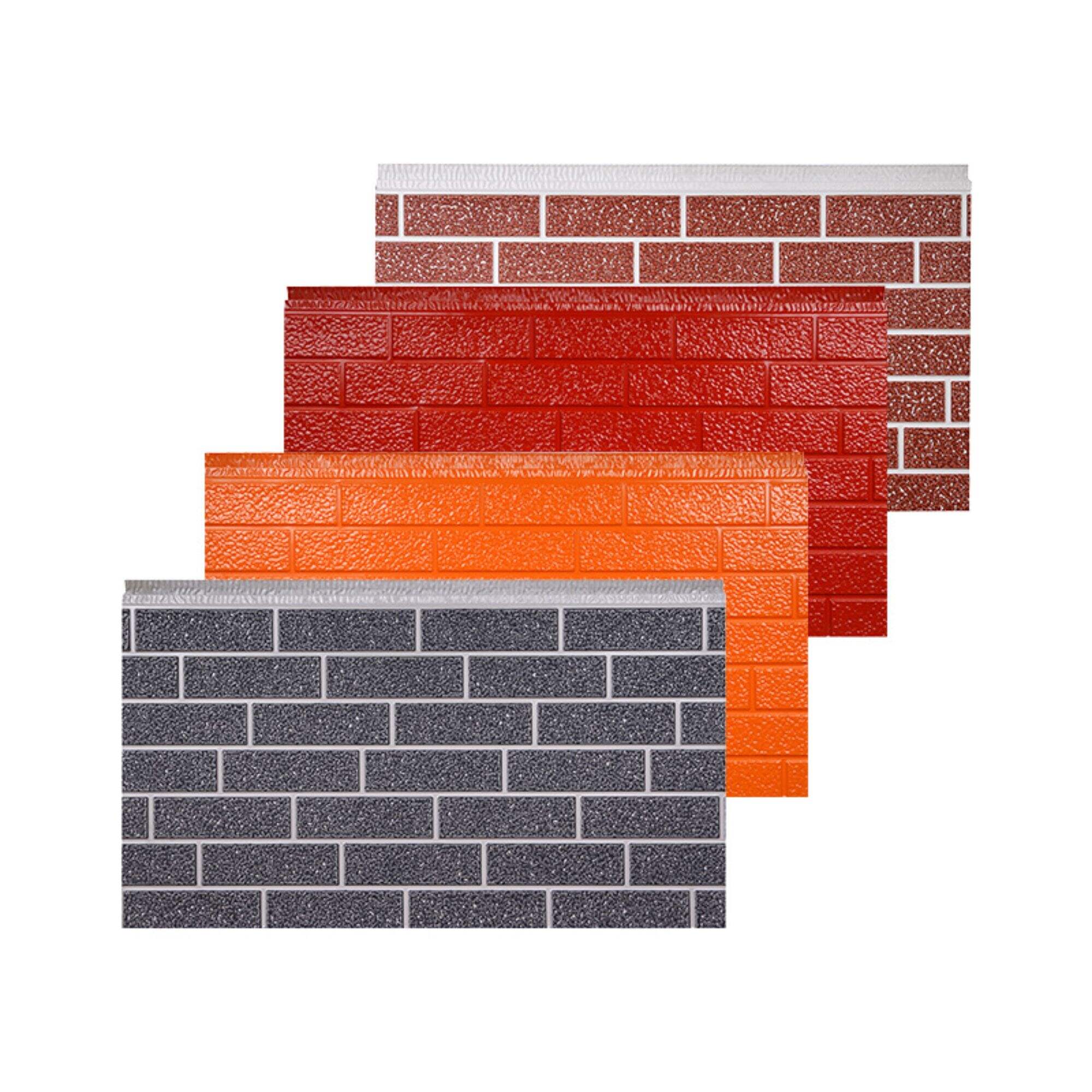

Our products can be customized to include trademarks packaging, quantity, trademarks as per customer needs. Our products may be totally smooth or smooth or textured. Color, size and trademark can be modified to suit your the requirements. Our foam sandwich an impressive supply capacity, high-tech skills and advanced equipment meet demands of customers.

Our products are easy to install and save energy. They can also help reduce expenses. The wall panels are lightweight, space-saving, earthquake-resistant and crack-resistant; they are also fire-resistant waterproof, water-proof and soundproof, ensuring with a quiet and comfortable environment; they environmentally friendly, green and durable. They are also highly foam sandwich and are widely employed.

To safeguard the interests of our customers protect their interests, we provide high-quality products at competitive price. Every customer treated like we would our foam sandwich and we treat them as such. We work with all customers regardless of where they are from. New designs launched in each category every year. The products are made with the highest quality and fully tested for quality.

Copyright © Shandong Qigong Environmental Protection Technology Co., Ltd. All Rights Reserved Privacy Policy Blog