Les panneaux sandwich EPS sont des matériaux spéciaux utilisés pour la construction de maisons, d'entrepôts et de nombreux autres types de bâtiments. Vous avez le choix de faire fabriquer ces panneaux avec une couche d'isolation en mousse entre deux pièces rigides. Ils auront des panneaux rigides et peuvent être fabriqués en acier ou en aluminium. L'isolation en mousse est un matériau qui protège le bâtiment de la chaleur extrême en été et du froid glacial pendant l'hiver. Par conséquent, les gens peuvent se sentir à l'aise dans ces bâtiments tout au long de l'année. De plus, les panneaux sandwich EPS sont légers et peuvent être soulevés facilement pour les opérations. Ils le sont grâce à leurs propriétés qui les rendent un choix idéal pour de nombreux projets de construction variés.

Il existe de nombreuses applications dans l'industrie de la construction liées aux panneaux sandwich EPS. C'est pourquoi on les voit souvent utiliser pour construire des entrepôts et usines gigantesques qui exigent un matériau capable de résister à des conditions quotidiennes sévères. De plus, ces panneaux sont excellents pour la réduction du bruit et peuvent donc être facilement utilisés dans des studios d'enregistrement, des salles de concert ou des pièces insonorisées, etc. Pour les lieux qui mettent l'accent sur la qualité sonore, l'utilisation de panneaux sandwich EPS peut faire des merveilles.

Construction de maison : L'autre activité que servent couramment les panneaux sandwich EPS est la construction d'une maison. Ces panneaux sont également couramment utilisés comme matériaux pour les murs extérieurs et les toits dans les bâtiments domestiques, car ils peuvent gérer l'isolation de manière extrêmement efficace et réduire les bruits extérieurs. La résistance à l'eau, la durabilité et la prévention de l'humidité sont les avantages du mousse qui maintiennent les maisons au chaud (et calmes), assurant le confort des résidents. De plus, ces panneaux sont très faciles à installer et peuvent économiser du temps sur le chantier ainsi que les coûts de main-d'œuvre pour la maison.

Ces produits sont extrêmement utiles pour l'industrie de la construction et constituent un choix populaire pour bâtir des structures énergétiquement efficaces comme les panneaux sandwich EPS. Elle a dit que l'isolation en mousse maintient les bâtiments chauds en hiver et frais en été. De cette manière, les panneaux permettent de réduire vos factures d'électricité et peuvent ainsi se rentabiliser en quelques mois grâce aux économies d'énergie réalisées. De plus, le poids léger et l'installation facile des panneaux sandwich EPS permettent aux constructeurs de faire des économies d'énergie pendant la construction.

Résistance et coût avantageux des panneaux sandwich EPS. Conçus pour résister aux intempéries, à la moisissure et au mildiou afin qu'ils ne se fissurent ni ne s'écaillent. Cela en fait un matériau nécessitant peu d'entretien par rapport à la plupart des autres matériaux de construction couramment utilisés (bois, béton) qui exigent souvent des traitements périodiques et des retouches sur une longue période.

Les panneaux sandwich EPS sont à la fois robustes et abordables. Une fois sur le chantier, ces panneaux légers peuvent aider les constructeurs à économiser de l'argent sur le transport et l'installation. En particulier dans les projets de construction où la réduction du budget dans ces domaines peut avoir un impact significatif sur les économies de coûts du projet. Selon votre budget ou les besoins spécifiques de votre projet, vous pouvez choisir parmi une variété de tailles et d'épaisseurs.

Enfin, l'utilisation de panneaux sandwich EPS dans votre construction accélérera tous les processus. Cela rend ces panneaux faciles à transporter et à déplacer sur le chantier, nécessitant moins de temps pour le travail manuel car les constructeurs peuvent terminer leurs tâches de construction plus rapidement qu'en utilisant d'autres matériaux de construction - ce qui nous donne une grande raison non seulement liée à la durabilité mais aussi des points positifs. Cette rapidité peut être utile pour réduire les coûts de main-d'œuvre, ce qui pourrait compléter l'économie de temps et d'argent dans les projets de construction, que ce soit pour les ouvriers ou les constructeurs de maisons.

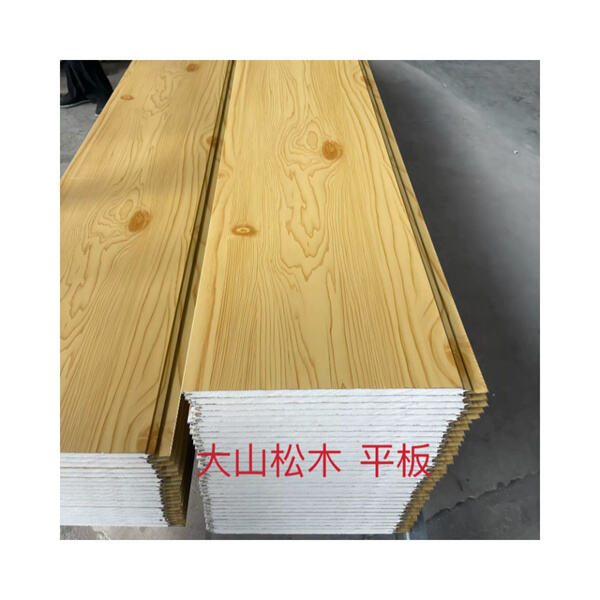

Nos produits peuvent être personnalisés, y compris le marquage, l'emballage, les quantités et même les marques déposées, selon les spécifications du client. La surface de nos produits peut être constituée de panneaux sandwich EPS lisses ou rugueux. La couleur, la taille et la marque de nos produits sont modifiées pour répondre à vos besoins spécifiques. Nous disposons d'une forte capacité d'approvisionnement, d'une expertise hautement technologique et des équipements les plus récents pour satisfaire les besoins de nos clients.

Nos produits sont simples à installer et permettent d'économiser de l'énergie. Ils peuvent également contribuer à réduire les panneaux sandwich EPS. Les panneaux muraux légers, dotés d'un faible encombrement, sont résistants aux séismes et à l'abrasion. Ils sont également ignifuges, imperméables, étanches et insonorisants, vous offrant un environnement calme et confortable ; ils sont écologiques, verts, extrêmement durables et largement utilisés.

Nous offrons un service de haute qualité après-vente. Nos produits peuvent être expédiés vers n'importe partie du globe dans des délais rapides, à un prix abordable, avec un excellent service de qualité supérieure. Notre entreprise dispose d'une équipe chaleureuse de panneaux sandwich eps. Les sociétés de transport les plus renommées proposent des expéditions privilégiées.

Nous veillerons toujours à garantir la qualité et la compétitivité des panneaux sandwich eps afin de protéger les besoins de nos clients. Nous accordons de la valeur à chaque client et les traitons comme une famille. Nous collaborons avec tous les clients, quelle que soit leur origine. Chaque année, nous lançons de nouveaux designs dans chaque catégorie. Tous les produits, exquisément fabriqués, sont intégralement vérifiés à 100 %.

Droits d'auteur © Shandong Qigong Environmental Protection Technology Co., Ltd. Tous droits réservés Politique de confidentialité Blog