Metal Cladding Panel Core Materials Comparing PU、EPS Foam、Rock Wool

Selecting the right core material is a critical technical decision in metal cladding panel specification. PU/EPS foam and rock wool cores dominate the market, each offering distinct performance profiles impacting safety, efficiency, durability, and application suitability. This comparison outlines their key characteristics based on inherent material properties and standardized testing.

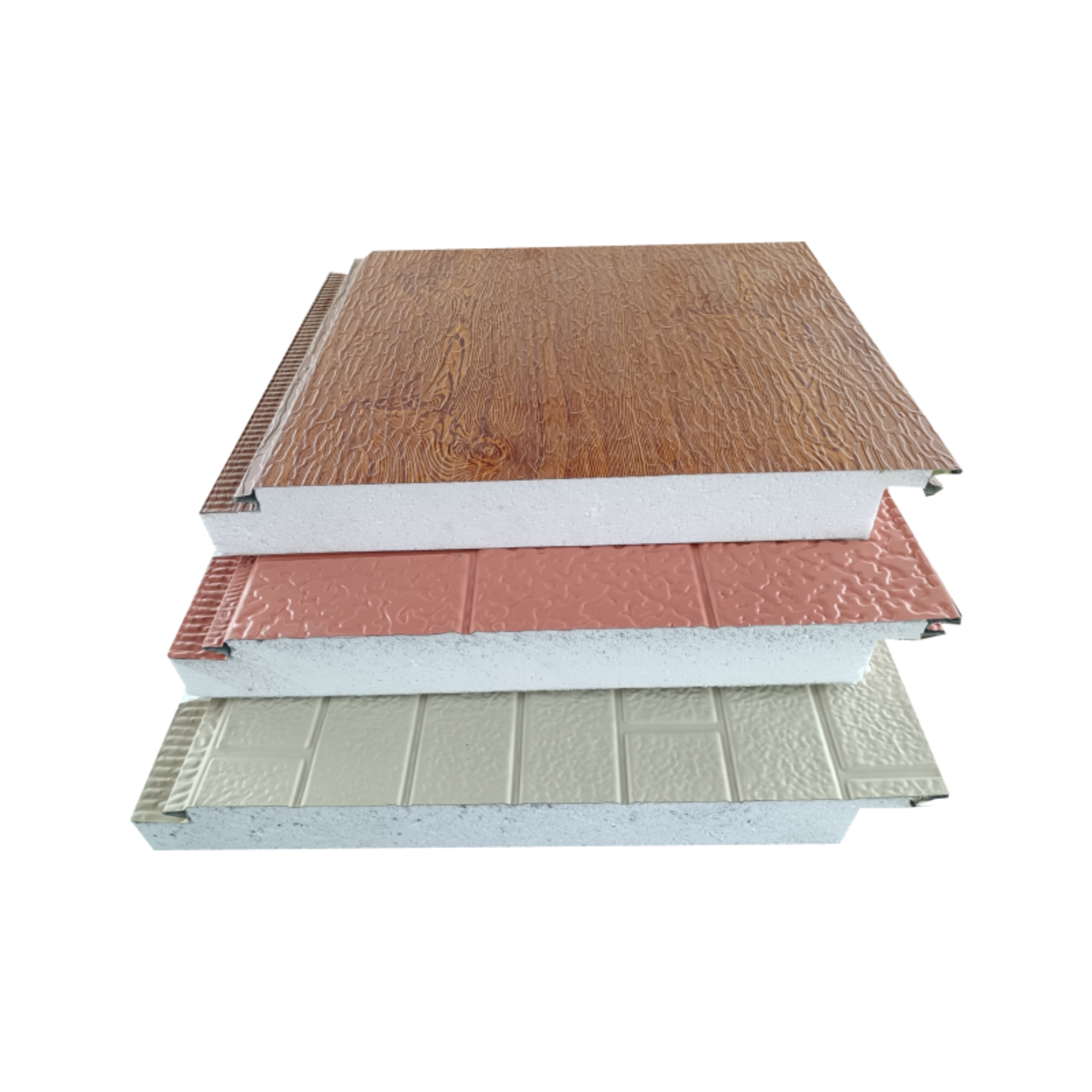

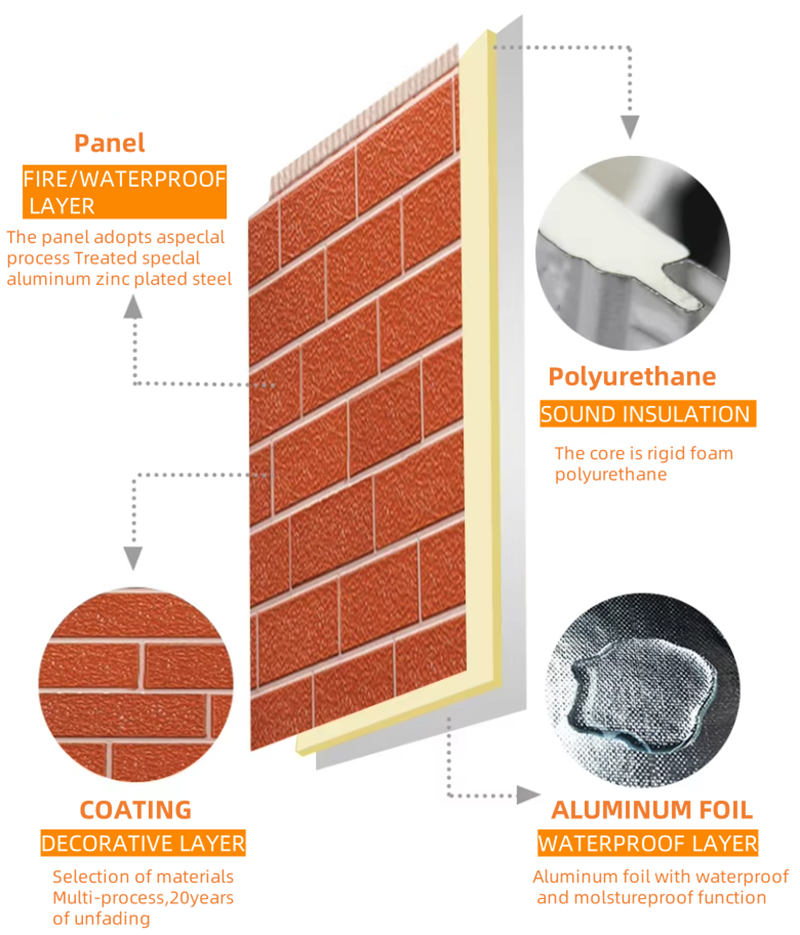

1. Polyurethane (PU) Cores

Thermal Performance: PU/PIR foam offers the highest thermal insulation efficiency (lowest thermal conductivity, typically 0.022-0.028 W/(m·K)). This translates to thinner panels achieving required insulation values (R-values/U-values), optimizing space and potentially reducing structural loads.

Structural Contribution: Provides high compressive strength (usually >150 kPa), enhancing the panel's overall rigidity and load-bearing capacity, beneficial for roofing and demanding structural applications.

Weight: Very lightweight, simplifying handling, transportation, and installation logistics.

Limitations:

Fire Performance: Standard PU foam is combustible (typically Euroclass E or lower). While fire-retardant (FR) grades exist (often reaching Euroclass B), they do not achieve non-combustible status. Smoke development during combustion can be significant.

Moisture Sensitivity: Requires robust, intact facings and sealed edges to prevent water ingress, which can degrade insulation value and potentially cause corrosion.

Chemical Compatibility: May be susceptible to degradation from certain solvents or adhesives.

2. Expanded Polystyrene (EPS) Foam Cores

Cost Effectiveness: Generally the most economical core option.

Thermal Performance: Offers good insulation (thermal conductivity ~0.032-0.040 W/(m·K)), though less efficient than PU, requiring thicker cores for equivalent R-values.

Moisture Resistance: Resists water absorption relatively well if facings remain intact, retaining insulation properties when damp (unlike mineral wool).

Weight: Very lightweight.

Limitations:

Fire Performance: Standard EPS is highly combustible (Euroclass F/E). Flame-retardant grades (FR-EPS) are available (typically Euroclass E/D), but still far from non-combustible. Melting and significant dripping occur during fire.

Structural Contribution: Lower compressive strength (typically 70-150 kPa) compared to PU.

Long-Term Stability: More prone to potential long-term creep under sustained load compared to rigid foams or rock wool.

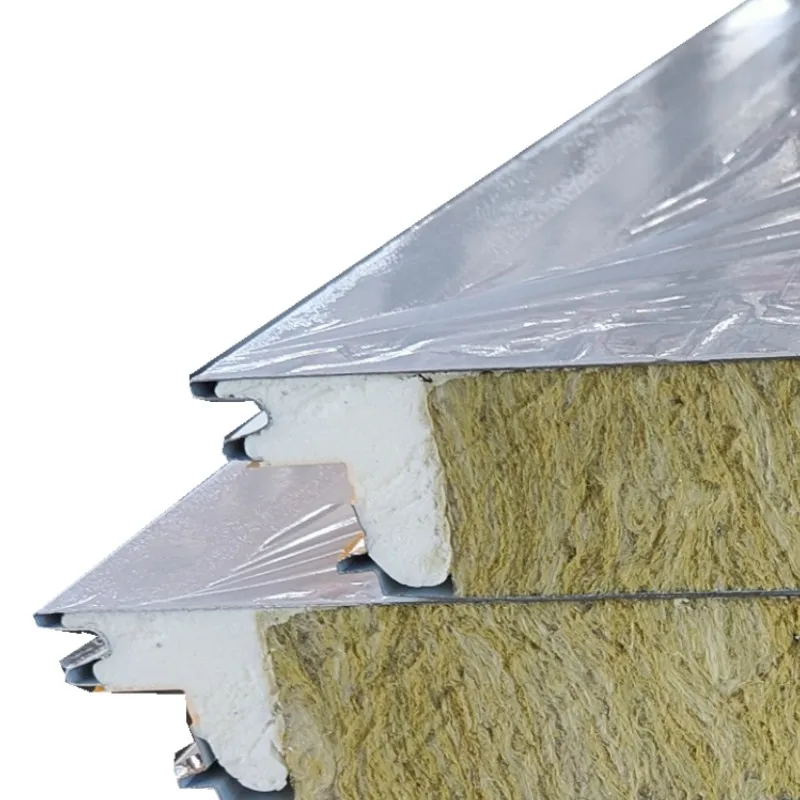

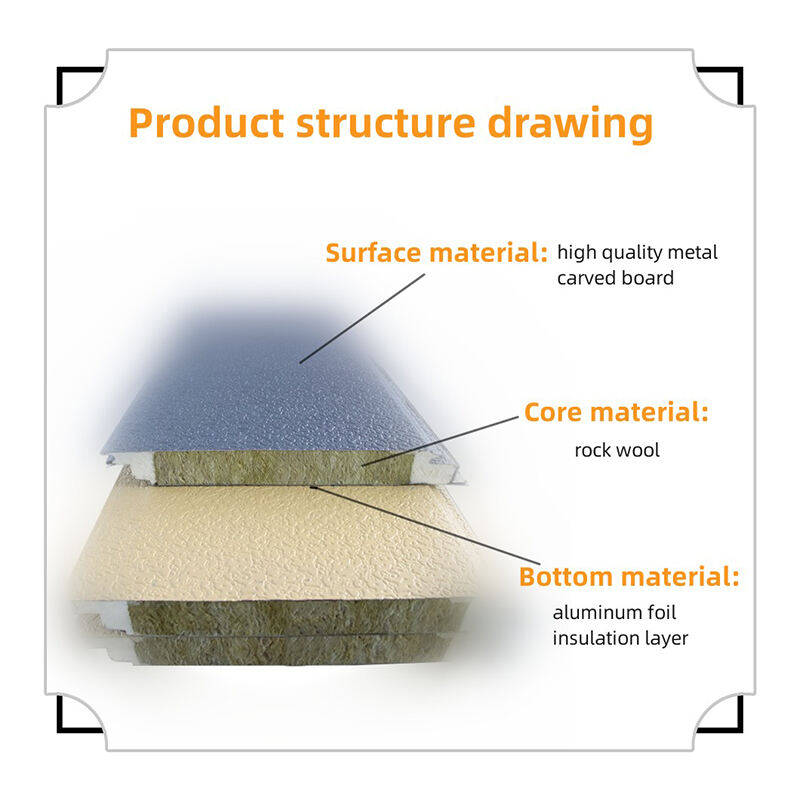

3. Rock Wool Cores

Fire Performance: The primary advantage. Rock wool is inherently non-combustible (Euroclass A1 or A2-s1,d0). It does not contribute to fire load, significantly delays fire spread, maintains structural integrity at high temperatures, and produces minimal smoke. This is crucial for buildings with stringent fire safety regulations (high-rises, public buildings, near boundaries).

Acoustic Performance: Superior sound absorption and insulation properties compared to foam cores, reducing airborne and impact noise transmission.

Thermal Performance: Functional insulator (thermal conductivity ~0.035-0.040 W/(m·K)), similar to EPS but less efficient than PU. Requires thicker panels for equivalent thermal performance.

Durability & Stability: Chemically inert, resistant to moisture (though wetting reduces insulation value temporarily - it recovers upon drying), rot, and pests. Excellent dimensional stability under temperature fluctuations. High compressive strength (>80 kPa, often >120 kPa).

Sustainability: Made from abundant volcanic rock and recycled content (slag). Fully recyclable at end-of-life.

Limitations:

Weight: Significantly heavier than foam cores, impacting handling and structural support requirements.

Cost: Typically the highest cost core material.

Thermal Bridging: Requires careful detailing at joints and fixings to minimize thermal bridging due to its fibrous nature, compared to the more continuous insulation barrier of foams.

Core Material Comparison Summary:

| Feature | PU Foam | EPS Foam | Rock Wool |

| Thermal Conductivity (W/mK) | 0.022 - 0.028 (Best) | 0.032 - 0.040 (Good) | 0.035 - 0.040 (Good) |

| Fire Reaction | Combustible (E/B FR) | Combustible (F/E/D FR) | Non-Combustible (A1/A2) |

| Acoustic Performance | Moderate | Moderate | Excellent |

| Compressive Strength | >150 kPa (High) | 70-150 kPa (Moderate) | >80-120 kPa (Mod-High) |

| Weight | Lightest | Lightest | Heaviest |

| Moisture Resistance | Good (Sealed) | Good (Sealed) | Good (Drainable) |

| Primary Application Focus | Thermal Efficiency, Structure | Cost-Effective Insulation | Fire Safety, Acoustics |

Selecting the Appropriate Core

The optimal core depends on project priorities:

Maximum Thermal Efficiency (Minimal Thickness): PU foam is unmatched.

Lowest Initial Cost: EPS foam is often the baseline.

Critical Fire Safety & Compliance: Rock wool is the definitive choice where non-combustibility is mandated or highly desired.

Superior Acoustic Control: Rock wool provides significant advantages.

Structural Load Requirements: PU offers the highest inherent strength.

Understanding these core material properties allows architects, specifiers, and contractors to make informed decisions aligned with specific building performance requirements, safety codes, and budget constraints. Technical datasheets and fire test reports from manufacturers should always be consulted for precise product performance data. Explore detailed technical specifications and project case studies in our resource library.

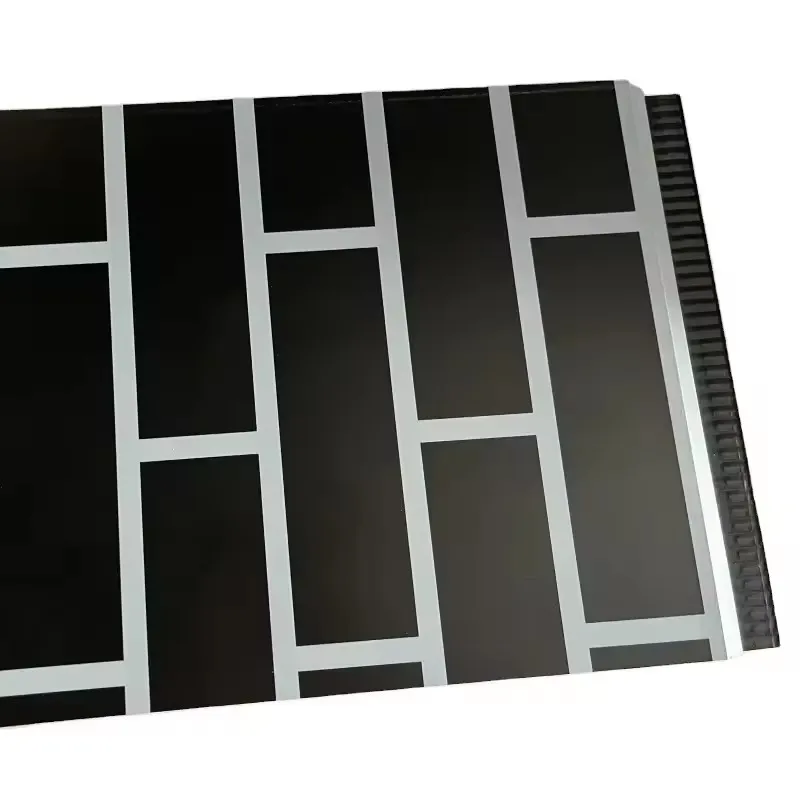

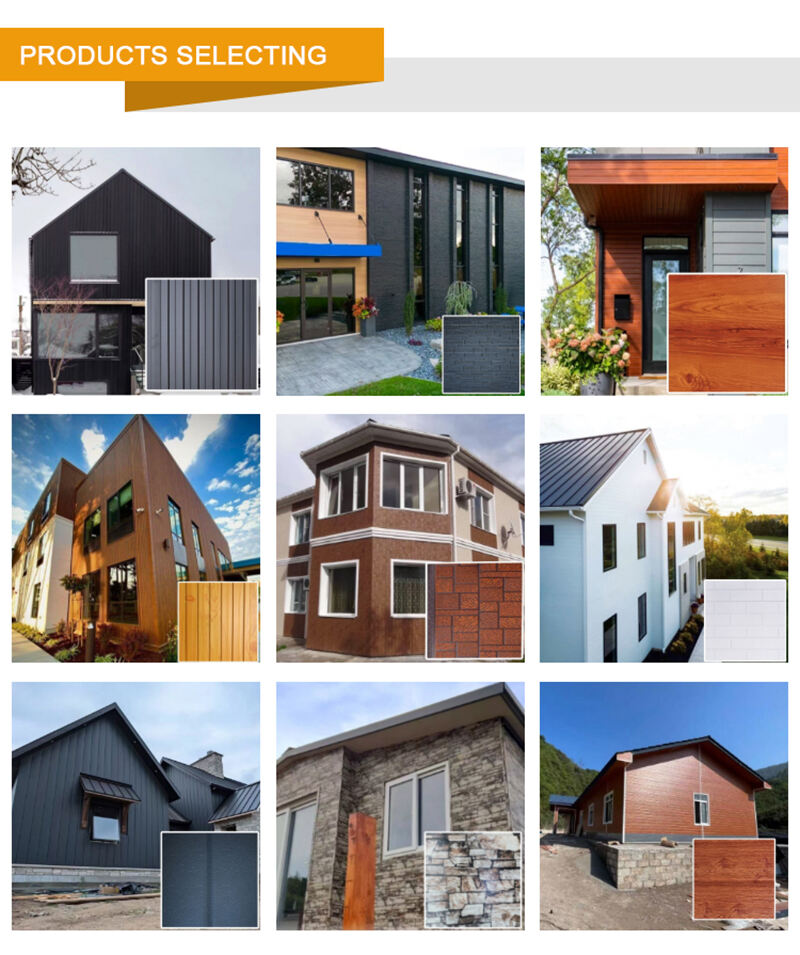

Recommended Products

Hot News

-

Shandong Qigong Metal Engraving Panel Company launched the latest panel pattern at The 16th China Int'l Integrated Housing Industry &Building Industrialization Expo

2024-10-17

-

October 2023 Malaysia Building Materials Exhibition

2024-01-25

-

August 2023 Guangzhou Housing Expo

2024-01-06

-

June 2023 Foreign Customers Visit The Factory

2024-01-06

-

April 2023 Canton Fair

2024-01-06

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

VI

VI

TH

TH

TR

TR

MS

MS

HY

HY